The choice of high-quality tile adhesive is not as simple as it seems, because modern brands offer a huge range of such products. However, among all this diversity, many buyers prefer Unis Plus glue. To understand its relevance, you need to know the features, specifications, advantages and disadvantages.

Features

Unis Plus tile glue is a development of a domestic manufacturer engaged in the production of stucco mixtures for more than 20 years. It is designed for indoor and outdoor use. The product is a dry mix with a balanced formula, characterized by a grayish tint. It is sold in packages of 25 kg, in addition, if desired, you can purchase the option of packing 5 and 23 kg. The basis of tile glue is cement, in addition to it, mineral fillers and chemical reagents are included in the composition. Due to them, the material acquires high technical characteristics.

This glue is part of the group of universal materials for decoration and is designed to work with non-deformable types of substrates. This composition is suitable for work with the decoration of buildings above the basement. It can be used for decorating vertical and horizontal planes inside rooms with a normal and high degree of humidity. Glue is characterized by high strength, which distinguishes it from other varieties of adhesive analogues of the brand. It can be used in the installation of the "warm floor" system, when you have to work with complex bases.

In addition, the solution allows laying on an old tile floor, while the adhesive firmly fixes the tile to the working surface. Having a high adhesive ability, you can put the fragments in a top-down manner. In addition to the "warm floor" system, this glue allows facing on ceilings heated to +70 degrees. Due to its plasticity, it differs in convenience in work, does not flow down from vertical bases, which simplifies the process of fixing dies. After the adhesive gains its strength, it does not change its characteristics in contact with water, as well as at high subzero temperatures.

Scope of use

The type of base when working with this tile adhesive may be different. For example, through this composition, it is possible to glue the tiles to concrete floors, including cellular concrete and slag concrete. In addition, he well fixes the dies to cement, brick surfaces, gypsum floors (GKL, GVL, GGP). And also it is suitable when the working base is asphalt. In working with this glue, you can use tiles, ceramic tiles, porcelain tiles, natural and artificial stone, as well as mosaics, whether it is an option in the form of separate small dice or a modern analog on a special grid with a lined pattern and identical distances between the elements.

Like other analogues, the mixture has a certificate of compliance with safety standardsthat allows you to use it in the decoration of child care facilities (kindergartens, schools, clinics, special educational and gaming centers, studios). This glue allows you to perform high-quality and durable lining of terraces and arbors. It is used for structures not only closed, but also open type. This composition is actively used for decorating staircases. For example, together with the original tile, it allows you to give the stone stairs a more aesthetic appearance, ennoble them and making the interior of the room special. In fact, it is used everywhere: in medical institutions, industrial facilities, decoration of offices, private and apartment buildings. Moreover, it is appropriate in almost any room of the home, whether it is a home library, study, bay window, joint or separate bathroom, kitchen, living room or other room.

Characteristic

This glue is universal and can be used for various work both indoors and outdoors. He has a cement base with mineral fillers and other chemicals, thanks to which this mixture has high-quality technical characteristics:

- High coefficient of adhesion.

- Moisture-proof, which is especially important for facing rooms with high humidity or pools.

- Resistance to temperature changes. Adhesive properties do not change regardless of weather conditions. It withstands temperatures from -50 to +70 degrees.

- The mixture has an environmentally friendly composition, so it does not cause allergies.

- The solution, and with it the tile, will not begin to slide off the wall, because the adhesive has plasticity. It is firmly fixed to the surface.

The mixture is easy to prepare and apply, while the consumption of glue is quite economical and is about three to four kilograms per 1 m2 (here it all depends on the size of the tiles). The mixture is usually sold in bags weighing 25 kg, which simplifies the task of calculating the amount of glue for a particular finishing work. Packages of 25 kg are enough for an area of 8 square meters. The glue dries in twenty-four hours.

How to prepare the surface?

To tile lay evenly, you must first carefully work with the base and perform its preparation as follows:

- The old finish is removed, whether it be screed or crumbling plaster.

- If the surface is in cracks and other defects, then the base is leveled with plaster.

- The surface should be dry, without any dirt and oil stains.

- If the room is with high humidity, then before work it is better to perform the waterproofing procedure.

- The primer is necessary so that the laying base is even. So the grip will be more reliable and durable. If the surface is not leveled, then the tile will begin to peel off or crack over time. It is better to prevent these consequences in advance.

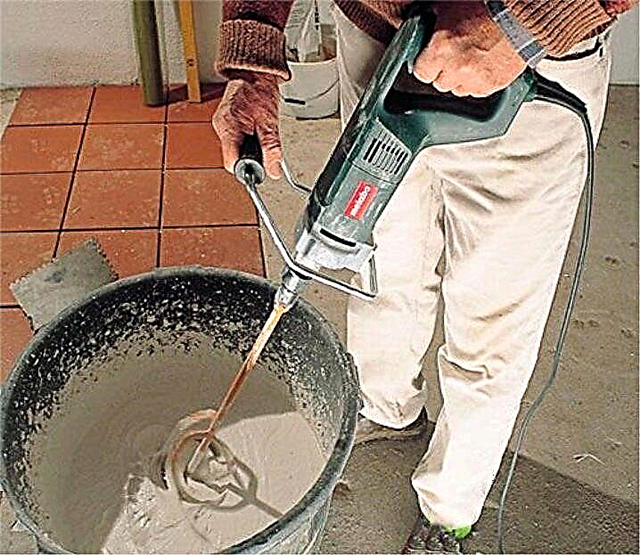

How to knead a solution?

A suitable container will be required for this procedure. All tools should not be dirty.

The algorithm of work.

- Glue must be diluted in the ratio of 250 ml of water per 1 kg of dry composition.

- Then for three to five minutes, the resulting mass must be stirred. This is best done with a special mixer or drill, which has a special nozzle. If none of the above is available, then you can stir the glue by hand. The result should be a homogeneous consistency.

- It is important to remember that the properties of the mixture after cooking last only three hours, so it is important to correctly calculate the amount of glue needed for a certain amount of work. When thickening, the mixture is mixed again, while water is not necessary to add.

- If you do not observe the proportions, add additional components to the solution, do not follow the recommendations in the instructions, then the resulting mixture may not correspond to the declared characteristics.

How to apply?

After the surface is prepared, and the glue looks like a homogeneous consistency, you can start applying it to the wall or floor.

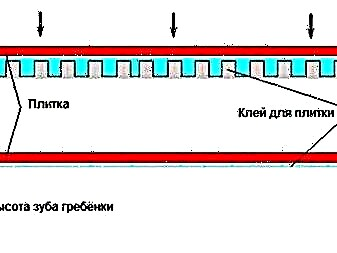

A spatula will be required for this process. Using it, an even layer of the composition with a thickness of 3 to 15 millimeters is applied, we must not forget to level it with a special grater or a spatula with cloves. If the squares of the tiles are large, then the teeth should be from 8 millimeters.

It is important to monitor the even distribution of the adhesive mass. Voids will turn into unpleasant consequences in the future, so it is better to press the tile a little to the surface.

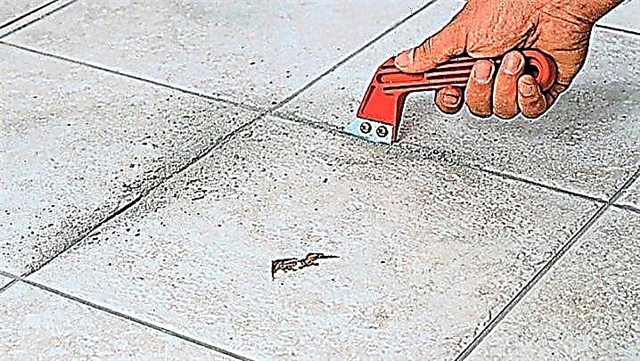

After the material is laid, it can still be adjusted within twenty minutes. The glue dries exactly one day. Then you can move freely on the tile (if the finishing work was carried out on the floor). After the work is completed, you need to remove the excess adhesive mass that remained on the front of the tile and grout joints. If the excess composition remains in the seam, then a number of problems may arise when grouting begins.

Possible consequences.

- If you grout the uncleaned seam, then in the future it will begin to crack, because it will be thin.

- Another reason why glue residue must be removed is aesthetics. If the adhesive mass peeks through the grout, no matter how beautiful the tile is, its appearance will be spoiled.

- Using colored grout on the seam with glue residue will result in the fact that after drying it will differ in color with the rest of the grout. The thing is that in this place it will be thin and not so strong. The result will be sloppy.

To avoid these unpleasant consequences, you need to remove the remnants of the glue while it is in a soft state, otherwise it will be much more difficult to do later. For the procedure you will need a knife. Using its blade, it is easy to remove the adhesive residue from the edges of the tile.

If the mixture is already frozen, then you need to use a special knifewhich is intended for a trowel seam. First you need to make a cut in the center of the seam and scrape with a knife dry glue from the edge of each tile. If necessary, you can clean the tiles using an abrasive grater. And at the end of the procedure, the seams are cleaned with a vacuum cleaner so that no small particles remain from the glue.

Another important tip: after laying the tiles, do not immediately begin to overwrite the seams. It is necessary to wait until the glue “seizes”, its drying time is indicated on the package. If the adhesive mass is still wet, and the grouting process has already begun, then in the final result it may appear in a different color. Therefore, it is important to strictly follow all step-by-step instructions both in the dilution of glue and in its application.

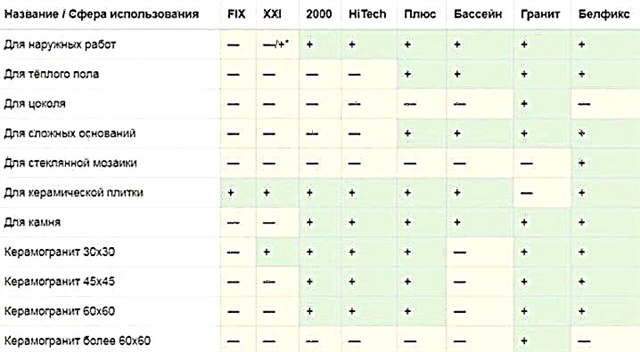

Unis offers a wide range of adhesives. Each of them is designed for a certain type of work and has individual technical characteristics.

As for the Unis Plus adhesive, it is universal, it can be used for various types of materials. It is safe and used for repairs in institutions with small children. The glue is suitable for any other finishing work (only facing the base is impossible with it). It is sold in red packaging.

Its characteristics:

- the applied layer should not be thicker than one and a half centimeters,

- glue properties do not disappear for three hours during operation,

- you can correct the tile after installation within fifteen minutes,

- glue dries 24 hours,

- withstands extreme temperatures from -70 to +50 degrees.

Unis 2000

This type of mixture differs from its predecessor in that it does not have high frost resistance, therefore it is not recommended to use it in extreme conditions. This glue is usually used for ceramics, concrete for internal and external wall cladding.

Features:

- the composition hardens after about 36 hours,

- it is possible to adjust the position of the tile within ten minutes after it is laid,

- temperature range during proper operation - from -50 to +50 degrees,

- glue is able to withstand a large tile weight - up to 80 kilograms per m2.

Unis XXI

This product is usually used for tiling floor and walls indoors and outdoors. It tolerates moisture well, which is its great advantage.

Specifications:

- the adhesive composition is applied in an even layer not exceeding ten millimeters,

- does not lose any of its properties for three hours,

- withstands temperature conditions from -50 to +50 degrees.

- weight restrictions - not more than 40 kilograms per square meter.

Unis Granite

This glue is able to withstand heavy weight (up to 110 kilograms per square meter), so with it you can work with stone slabs, as well as with granite. Suitable for decoration not only walls, but also the facade with a base. Its composition is safe, therefore it is widely used in child care facilities. Features:

- with this glue, you can not be afraid of the sliding of the plates, so it is used to finish not only walls and floors, but also ceilings,

- the solution has increased frost resistance, it is easy to work with it outdoors,

- the mixture dries for about 36 hours,

- sold in packages of 25 kilograms,

- to prepare a solution, you need a ratio of the mixture with water 5: 1,

- glue properties are preserved for three hours, and it is possible to adjust the location of tiles or other cladding within 10 minutes after installation.

Unis hitech

Complex adhesives lend themselves to this glue, while styling can occur either normally or in a downward direction.

Specifications:

- layers applied to one or another base can reach one and a half centimeters,

- material correction after installation can be carried out within fifteen minutes,

- the properties of the prepared solution are not lost until five hours of operation,

- environmentally friendly and does not cause allergic reactions,

- as for the flow rate of the mixture, it is three and a half kilograms per meter squared.

Unis Belfix

The glue is designed for complex work with such types of materials as tiles, marble, mosaics, etc. It is resistant to frosty weather and elastic. It can be used both for exterior and interior decoration, especially including wet rooms. Its cost is higher than its predecessors.

Properties of this glue:

- for the preparation of a homogeneous mass, a ratio of 5: 1 is necessary,

- the adhesive layer is needed no thicker than one centimeter,

- error correction time when working with tiles - 15 minutes,

- like other types of glue, it does not lose its properties within three hours after preparation,

- operating temperature - from -50 to +70 degrees,

- the composition dries 24 hours.

Unis fix

This type of glue can be called the weakest among other assortment of this brand. It has a small price and is suitable for laying ordinary tiles in the bathroom, kitchen, on the balcony.

Main features of this product:

- the mixture is placed in water in a ratio of 5.5 to 1,

- applied layers should not be thicker than one and a half centimeters,

- you can adjust the position of the tile within ten minutes,

- drying time is twenty-four hours,

- this glue is sold in packages of 25 kilograms, but it is this type of mixture that is rarely seen on store shelves.

Unis Pool

Judging by the name, you can guess where this type of glue is used. Its area of operation is wet rooms and even the inner surface of pools or a jacuzzi. It is applied to ceramic tiles, mosaics, concrete, masonry, plasterboard coverings, old tiles.

Glue has a fairly high technical characteristics:

- moisture resistance, which corresponds to its intended purpose,

- glue withstands temperature extremes of one hundred degrees,

- the material is spent economically - a little more than three kilograms per meter squared,

- the solution does not lose its characteristics three hours after dilution, therefore, it is necessary to calculate the required amount of the mixture for a certain area (this applies to large areas) and divide the mixture into portions,

- that sways the thickness of the applied layer, then it should be 3-6 millimeters,

- for correction and alignment of errors on the tile there are ten minutes,

- the glue dries during the day, during this time it is forbidden to walk on the tile (if finishing work was done on the floor),

- operating temperature - from -50 to +70 degrees.

These are the main types of Unis Plus glue. Each of them has its own technical characteristics and is used for a certain type of facing work. You should pay attention to the listed properties so as not to make a mistake in choosing the adhesive of this brand.

Product Advantages

The feedback from customers who purchased Unis Plus Adhesive for finishing work is mostly positive.

Among the advantages of this product are:

- rich assortment (for different types of surfaces),

- convenient packaging of 25 kg

- durability and profitability,

- glue is easy to spread and apply,

- for each type of product attached instructions for use, which greatly facilitates the work with this composition,

- glue is made in accordance with GOST and has all certificates of conformity.

Unis Plus - quality products at an affordable price.suitable for cladding a wide variety of surfaces. The main thing is to follow the instructions for use, and the end result will be pleasing to the eye for many years.

A comparison of tile adhesives from different manufacturers is clearly presented in the video.

Benefits

- High rate of durability.

- Good adhesion to all types of substrates.

- The glue line does not lose its properties when the temperature decreases or rises, but only frost-resistant glue is able to withstand frost, which can withstand even the conditions of the Far North.

- The composition is environmentally friendly, does not have a pungent odor, without toxic fumes.

- At the same time, gluing of the cladding and leveling of the base is carried out.

- The density of the composition prevents the tiles from sliding even from vertical or inclined bases.

- Thrift. The consumption of tile glue is small, its value varies slightly depending on the type.

- Long shelf life of the finished solution. There is enough time to lay the tile, adjust its position and fix it securely.

- Moisture resistance.

- It can be used during the installation of underfloor heating.

Disadvantages

- Most adhesives are gray in color, so they cannot be used for laying transparent and half transparent tiles.

- For classic mixtures, the maximum weight of the glued tile is 100 kg / m. sq.

- The base needs careful preparation.

- On a surface with defects and height differences of more than 0.5-0.7 cm, use without leveling the base is not recommended. Leveling mixtures are used.

- It is impossible to work in frosty weather.

Varieties

Powdered formulations and adhesives are packaged in sealed paper containers of 5 and 25 kg.

Bags should be stored in dry rooms on wooden pallets to prevent them from becoming damp.

The shelf life of the adhesive, subject to conditions, is 1 year. Each package contains instructions for use.

Eunice Plus

It is used for laying tiles of any type. Porcelain tile, mosaic, stone are glued. This is the most durable tiled composition of the entire line.

The strength of Eunice Plus is 1.25 MPa, it is able to withstand up to 1 kg of facing material per 1 sq. M.

The main purpose of the adhesive is tiling and porcelain stoneware indoors, the exterior finish, except for the plinth lining, the arrangement of a warm floor and laying tiles on complex foundations, including the old lining.

The composition is harmless, so it can be used in children's institutions.

You can fix the tile on the following bases:

- gypsum,

- drywall

- gypsum board.

Eunice 2000

Eunice 2000 is intended for the installation of ceramic tiles and kerogranite with a side size of 600 mm. It is used indoors and outdoors. Tile is glued on vertical and horizontal planes, on concrete, gypsum, cement, brick. The composition aligns surface defects and height differences with a depth of not more than 1.5 cm. They are used in medical and child care facilities.

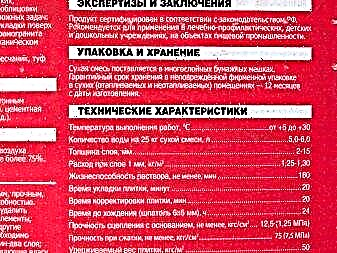

Specifications

Physical and mechanical The characteristics of Unis Plus tile adhesive look like this:

- the life cycle of the working solution is 3 hours,

- laying time should not exceed 20 minutes from the moment the solution was applied to the work surface,

- the time for adjusting the stacked fragment should not exceed 10 minutes,

- range of layer thickness depending on the length of the spatula teeth - 3–15 mm,

- temperature during lining - from +5 to +30 degrees,

- compressive strength is 7.5 MPa,

- humidity in the room at the time of operation - not more than 75%,

- the amount of water per bag with a volume of 25 kg is 5–5.5 l,

- approximate consumption per 1 m² with a length of trowel teeth - 3.5–4.5 kg / m²,

- frost resistance is at least 35 cycles,

- raw material consumption with a thickness of 1 mm is 1.25–1.30 kg / m²,

- the retained weight of the tile with the adhesive is 100 kg / m²,

- the drying time of the solution under the tile is 24 hours,

- the operating temperature of the finished coating varies in the range from -35 to +70 degrees,

- adhesion level with a working base reaches 1.25 MPa.

The mixture requires proper storage. It is important that it is in a dry room, and the kraft bag in which it is located is not damaged. At the same time, you can’t put it on a cold floor: the bag should stand on a wooden pallet. Subject to these conditions, it is possible to store the dry composition for cladding for no more than 12 months from the moment of its production.

Foundation preparation

Not a single tile adhesive will hold long and firmly unless preliminary preparation of the base is carried out. To do this, the surface is cleaned of the old coating, all that is poorly adhered and peeled off is removed, since the lining will not adhere well and for a long time on such a basis. After that, the base is removed with dust using a semi-dry sponge. Then the working surface is strengthened by means of a primer solution using a deep penetration composition. After the soil degreases the surface, binds dust microparticles and tiny cracks, the surface is leveled with rough plaster. Then primed again. After the soil has dried, you can begin to surface the surface.

Instructions for use

The adhesive is diluted according to the instructions indicated by the manufacturer on the back of the package. It must be bred before the immediate start of the workflow. Subject to the proportions indicated by the seller, the master obtains a pasty mass of homogeneous consistency. After the initial stirring, the solution is left and re-mixed after 5-7 minutes. Then proceed to the main process. Glue is gathered with a trowel and distributed on a small section of the wall (about 2–4 small tiles). After it is carried out with a notched trowel, removing excess weight. Next, take a die and smear glue on its back surface. The excess is again removed with a notched trowel. But now in the direction perpendicular to what is on the working surface. This will avoid air pockets and will contribute to a more durable adhesion of the composition to the tile and base.

Then the die is pressed to the base and slightly shifted back and forth, after which it is installed in its place. The shift will also allow you to get rid of excess voids. After installation in place of the first element take the second and in the same way install it next to the first. However, here it is already necessary to observe the same voids between the elements, since different distances between the parts will make the finished look of the cladding messy. The size of the seams depends on the size of the element. Usually the larger it is, the greater the gaps can be, however, the craftsmen do not recommend making too wide seams in the finish, since the seams themselves are a sore spot in the finished tile. Too narrow distances will produce imperfect geometry.

In order not to suffer with each distance and crosshairs, it is better to use special crosses. This will allow you to control the distance between the dies and see when it is not enough (crosses should not fall out, they should be well pressed with tiles). At the end of the work, immediately wash the equipment. Remove excess glue in the process. You can not do this when the composition hardens, and even scraping off the tiles. From this, scratches will remain on the surface.

After the solution under the tile dries, remove all the crosses that were used during installation. After they take the grout mixture, dilute it as indicated in the instructions (usually water is also added) to the consistency of sour cream. After it, fill all the voids between the trim elements, and then wipe the entire surface with a dry sponge, removing the excess mixture. This finishes this, however, some masters, after the grout has dried, treat the finished coating with a special spray in the form of an aerosol.

When performing facing work, it is important to proceed to each subsequent stage only after the used material of the previous one has dried. Otherwise, the finished coating will not hold on the base for a long time without the need for repair.

Tips from professional craftsmen

When working with tile adhesive experts recommend paying attention to several nuances.

- The longer the glue is stirred automatically, the shorter its life cycle, which can shorten the working time and adjustments. It is better to mix the solution at low speeds of the construction mixer.

- For the identity of the seams between the elements, you can use not only plastic crosses, but also special clips. With their help, you can give the surface being trimmed the look of a professional styling with an ideal docking.

- The larger the tile size used in the work, the longer the teeth of the notched trowel should be.

- Glue can not be applied immediately to the entire working surface. This is done partially, spreading the finished solution on the basis of the approximate area, which can be glued over in 10-15 minutes. This is due to the fact that over time, the composition deposited on the base will change its properties, worsening the level of adhesion. Glue the tile to it immediately after application.

Reviews

Unis Plus tile adhesive in red packaging is highly rated by customers, as reviews on the Internet say. According to their opinions, it is easy to use, does not slide off the walls when laying tiles vertically, dries optimally quickly and does not crack under the tiles over time. At the same time, the mass is really economical. And in the case of a small missing volume, it can be purchased separately by choosing a packaging of 5 kg.

See Unis Plus glue review in the next video.

Eunice 21

It is used for ordinary tiles indoors and outdoors, on horizontal and vertical planes. You can plant kerogranite (porcelain stoneware) only on the floor, provided that its size does not exceed 30x30 cm.

Eunice 21 is a frost-resistant adhesive that can be used in freezing and wet rooms without constant contact with the liquid. It is allowed to give in to frost no earlier than 4 weeks after installation.

- Glue made in Moscow is intended only for interior decoration.

- Compounds manufactured by Chelyabinsk and Ulyanovsk enterprises are suitable for external and internal use.

Eunice Hitech

It is used for fastening complex cladding on ceilings, walls, and floor surfaces. Laying of material from bottom to top and top to bottom is allowed. The composition has an increased solution life and setting time. It can be used in medical and children's institutions.

25 kg of glue is enough for laying 7 sq. M. surface.

Eunice Granite

Glue for a tile of Eunis Granit fixes heavy and bulky plates. Natural stone and porcelain stoneware are planted on it on the floor, walls, basement, facades. Installation on an old covering and a heat-insulated floor is allowed.

The density of the mixture prevents the tiles from slipping during drying with vertical bonding.

Permissible use in kindergartens, schools, hospitals.

Eunice Belfix

Thanks to the white color, Eunice Belfix is used in the installation of glass mosaics, marble, natural stone and other types of complex cladding, for which classical cement compositions are not suitable. It has increased elasticity, frost resistance. They overwrite the seams. The cost of one bag exceeds 400 p.

The tile is mounted on the walls, floor (including with heating), in damp rooms.

Eunice Pool

Glues stone, ceramic tiles, mosaics in damp rooms and containers with water. Sealant Yunis Pool is used for exterior, interior decoration, in complex structures. Mounting on the old cladding is allowed, suitable for laying floor heating.

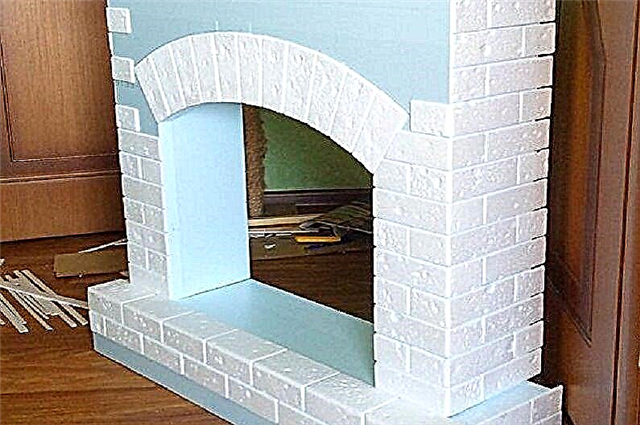

Heat glue

Unis is reinforced with a heat-insulating base, a substrate is made of mineral wool, glass wool, expanded polystyrene, marble, ceramics, tiles are fixed, furnaces and fireplaces are finished. To prevent fungus, the primer is treated with a primer before applying Heat-adhesive.

Heat glue is applied manually or by machine. It is an elastic compound that can be used with deformed bases. It does not interfere with air exchange in materials, therefore it is used to create breathable surfaces.

Recommended for fixing fiber insulation with high vapor permeability.

The finished composition is easy to use, it is plastic, does not emit toxic fumes when heated.

Eunice Horizon

Designed for pouring floors. It forms a seamless surface, evens out differences up to 0.1 cm. It is possible to level the floor, screed and bearing substrates by hand or by machine. Eunice Horizon is suitable for thick-, thin-layer leveling, arranging a warm, floating floor. Use is possible in heated rooms that do not freeze.

Rapido

Designed for gluing tiles up to 600x600 mm in size on horizontal and vertical planes in damp, dry rooms, with and without heating. Suitable for exterior cladding, gluing porcelain stoneware, used in the installation of underfloor heating. Due to the high adhesion, Rapido is used to plant cladding on staircases, marches, in industrial workshops, in warehouses, socles and at the entrance elements of buildings.

U 100

The base may be cement, gypsum plaster, screed, middle-aged concrete, including cellular, gas silicate, drywall, particleboard, OSB, painted surfaces. Due to the high strength and ability of the adhesive to withstand heavy loads, it is used when facing industrial, administrative, trading floors, when arranging parking lots, at stations, at airports, on stairs. The composition is heat-resistant, so they glue the finish on stoves, fireplaces, and are used when installing underfloor heating.

Surface preparation

- Cleaning the surface of the old finish, removing crumbling plaster or screed.

- Alignment of the base. Not leveling allowed height differences of no more than 0.1 cm per 1 sq. M. All defects, the depth of which exceeds this indicator, are plastered. Unis provides a wide range of plaster mixes. If you do not level the surface, the adhesive will be applied and dry unevenly, which provokes the delamination of the tile and the appearance of cracks on it.

- When the tiled cladding is laid on the old coating, serifs are made in a checkerboard pattern every 50 mm to increase adhesion.

- The base degreases and dries.

- When working in damp, basement rooms, waterproofing with mastic is recommended.

- The base is primed 1-2 times. Excessively porous surfaces are especially primed.

There is no need to pre-soak the tiles and base.

Solution mixing

To breed Eunice only in a clean container. The dry mixture must be diluted with water. The proportion of powder and liquid is indicated on the packaging of the adhesive. Next, the composition is thoroughly mixed until a homogeneous mass for about 3-5 minutes. The mixture is left at rest to ripen for 3-5 minutes. and mixed again.

You can breed it manually or with construction tools (mixer, drill with nozzle). Manual method at a time diluted not more than 1 kg of the mixture. Diluted glue is used for a maximum of 3 hours, otherwise it thickens.To give the composition a working consistency, it is again kneaded with a mixer without adding liquid.

If during cooking, the proportions are violated or other ingredients are added, the adhesion of the glue weakens.

Glue application

- The mixture is applied with a trowel or putty knife to the base. A layer with a thickness of 0.3-1.5 cm is aligned with the notched side of the spatula or grater comb. When working with large tiles, a spatula with teeth greater than 0.8 cm in height is used. The weight of the tile should not exceed the maximum permissible value.

- Tile is pressed to the applied adhesive layer. The distribution of the composition should be uniform without the formation of voids, this is achieved by wave-like pressing on the tiled surface or by tapping on it with a rubber hammer.

- When the material is stacked within 15-20 minutes, correction of its position and leveling is possible. So that the seams have the same thickness, special crosses are used.

The glue is applied to the surface area that is covered during the pot life of the mixture.

For outdoor work, when installing bulky tiles, marble slabs or when gluing on a porous, embossed surface, the composition is applied not only to the base, but also to the inside of the tile.

The drying time of the glue depends on its type, layer thickness and other factors, but on average within a day you can begin to grout the seams. When the tile is laid on a warm floor, heating is switched on only after 4 weeks.

Types of adhesive mixtures from Eunice and technical specifications

The most popular adhesives in the Unis line are Eunice Plus and Eunice 2000. The company also produces specialized compounds and progressive adhesives made using the most modern technologies. All adhesives are packaged in packages of 5 and 25 kg. It is important to store any mixture correctly: leave it only in a dry room, and on a wooden pallet so that it does not become damp. Shelf life under proper conditions is 12 months.

Eunice HiTech

This glue is used for finishing complex substrates. To create it, new technologies are used to improve the quality of adhesion to the tiles. Using glue, tile coatings can be mounted not only on vertical bases and on the floor, but also on ceiling surfaces and ceilings. It is permissible to lay the tiles by the method from top to bottom.

The characteristics of the tool are as follows:

- layer thickness - 3-15 mm,

- approximate consumption per square meter - 3.5 kg,

- frost resistance - up to 35 cycles,

- the held weight is 50 kg / sq. m

The viability of the solution is seriously increased - it is 300 minutes, the adjustment also increased to 15 minutes, and the working time after applying the solution is 25 minutes. You can use the coating after a day, as is the case with other brand adhesives.

Maxiflex

Maxiflex glue is a novelty among Unis products. This superelastic adhesive is specifically designed for deformable and complex substrates, including young concrete and wood-based panels. Using glue, it is possible to finish socles, steps and platforms of stairs, rooms subject to the highest loads (including metro stations).

Unlike other glues of the line, Maxiflex is packaged in packages of 20 kg. Its consumption is small - from 1.25 kg / square meter, it can withstand 100 cycles of freezing and thawing. The recommended layer thickness is less than 1 cm. You can operate the finished coating at temperatures of -40 ... + 100 degrees. The degree of adhesion with the base is high - 1.8 MPa.

Super Plus

Glue of this type is used for any non-deforming and deforming substrates. With it, you can finish all types of surface tiles, subject to high loads. The maximum size of porcelain stoneware that can be glued to Super Plus without additional mechanical fastening is 70 * 70 cm. Technical parameters are as follows:

- adhesion - 1.3 MPa,

- tile laying and adjustment time - 20 minutes,

- layer thickness - 2-25 mm,

- solution viability - 3 hours,

- time to surface operation - 24 hours,

- frost resistance - 100 cycles,

- operating temperatures - -40 ... + 80 degrees.

Flow calculator

Usually, all work with glue is carried out using a notched trowel, because Unis brand products do not require continuous application. The teeth leave empty furrows, therefore, glue consumption is reduced. So that it does not rise, it is better to process too uneven bases with plaster first.

The working layer should not exceed 15 mm, its minimum thickness is 2-3 mm. Usually, in the presence of a spatula with teeth 6.2 * 6.2 cm in size, the consumption varies from 3.5 to 4.8 kg with the largest thickness of the seam. A spatula, the teeth of which measure 3.1 * 3.1 cm, "picks up" less glue - up to 3.5 kg. Do not violate the proportions - dilute the adhesive with water should be strictly according to the instructions for use. Otherwise, the flow rate may change upwards. The preparation of too large portions of the solution also negatively affects the economy: if you do not have time to use up the glue, it will deteriorate.