Equipping country houses and cottages, people dream of a special atmosphere of silence, comfort. This is facilitated by wood fireplaces, which not only effectively heat the room, but also deliver a purely aesthetic pleasure from the contemplation of the fire.

In this article we will tell you how to fold corner fireplaces for a wood house, about their features and specifications. And our step-by-step instructions and the order of laying the corner fireplace will help even a novice to cope with this difficult work.

The fireplace stove has a number of undeniable advantages for owners of country houses. Most importantly, they can be equipped in homes where gasification is not provided or there are problems with electricity.

The fireplace is quick enough to melt, which allows you to provide warmth to your family even on a cool spring or autumn evening. And even where fireplaces are an additional source of heat, they will be an excellent solution in the off-season or during interruptions in electricity / gas.

Firebox

It can be closed or open in the fireplace. This does not affect the efficiency of heat transfer. When making a fireplace with a closed firebox, you will need the following elements: a gate, transparent doors made of heat-resistant glass.

A large role on the service life of the fireplace and its gate, transparent doors made of heat-resistant glass.

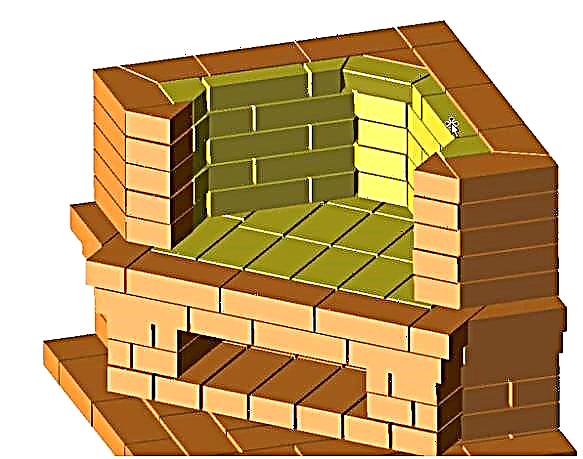

Turn out the materials from which it will be made. The outer part of the fireplace can be made of ordinary brick, but the firebox must be laid out of fireclay (heat-resistant).

Ready cast iron firebox will significantly reduce the time of laying the fireplace and simplify the task. To give the design a stylish authentic look, it will be enough to cover the cast-iron firebox with red brick and build a massive chimney.

Some stove stoves lay the inside of the finished cast iron firebox with chamotte brick to minimize the contact of metal with fire. This point is especially important in the case of using a steel furnace.

There is also such an element as a chimney tooth in the design of the fireplace. This is a small camera located on the back of the firebox at a slope of 20 0.

Between the ledge and facing there is a loaded platform, which has a size of 12.15 or 18 cm (depending on the total size of the combustion chamber). A chimney tooth passes a mixture of flue gases with cold air that travel at high speed.

Touching the walls of the chimney, the hot gas gradually cools, and it begins to sink down. Thus, gas turbulence is created in the pipe.

Gas movement in the fireplace (without a tooth and with a tooth)

If the combustion process in the furnace is not intense, then "freezing" of the smoke may occur. The purpose of the chimney tooth is to prevent this.

Another problem for good traction can be a fireplace portal that is too high in height. But this can be avoided by increasing the speed of movement of hot gas in the upper part of the furnace. Thus, air will suck from the room to the top of the portal.

This problem can be solved with the help of a chimney tooth - a small ledge that will allow you to squeeze the gas flow in the upper part of the furnace.

Ashpit (or blew)

Given the intensive combustion process of logs in the fireplace, a large amount of ash is formed, which is lowered into a special ash chamber located under the firebox. For the fire in the fireplace to flare up well and give off heat, you need excellent traction.

In case of ash clogging, the combustion chamber prevents air from entering the fire.

This point is especially important if you intend to use firewood from soft tree species, since they form ash most of all.

The blower is a small chamber located under the grate of the furnace.

This camera can be equipped with a drawer in the form of a drawer, or it can have a simple design with a door.

But not only the role of purification from combustion products plays an ash chamber. Through the blower, oxygen flows to the fire, which ensures intense combustion.

The blower door helps regulate traction and control the intensity of the fire. When opened, the flame intensifies. Accordingly, a closed door will block access to the fire, and firewood will slowly smolder in the fireplace.

If the design of the fireplace does not imply a door on the ash chamber, then the base of the combustion chamber must be done with a slight slope, in order to avoid spilling ash out.

But not all fireplaces have an ash pan. If the chimney pipe is high and provides good traction, then the wood will burn to the ground. In this case, the fireplace will be cleaned directly from the combustion chamber.

If it is located very low under the combustion chamber, near the floor and there is no way to make an ash chamber in the basement, then the stoves also lower this element.

Work processes in the fireplace are as follows:

- logs and firewood are laid in a metal grate and set on fire.

- The intensity of combustion is controlled by a slide gate, which opens or blocks access to oxygen. With an open type of furnace, the burning intensity can only be controlled by the number of firewood.

- As the wood is burned, the ash is collected under the grate, in a special ash pan, which must be regularly cleaned.

- Combustion products are discharged through a chimney.

- A separate base should be built under the brick fireplace. It is better to separate the foundation from the main one even at the construction stage, but if the fireplace project is already being implemented in the operated house, then you will have to remove part of the flooring, dig into the ground and build a separate foundation.

- All floor floors through which the chimney pipe will be discharged must be insulated with asbestos material. In the same way we isolate the walls that are next to the fireplace.

- If the fireplace is being built in a house with wooden walls, then between the adjoining wall it is necessary to lay a metal sheet, the size of which exceeds the dimensions of the fireplace by 20-25 cm on each side.

- When erecting a fireplace with an open firebox, it is necessary to lay a brick or ceramic tile in front of the fireplace so that accidental sparks and intense flames do not cause a fire.

- The fireplace is installed on a base made of fireclay brick.

- In no case should a dressing be made between the furnace and the lining. Otherwise, when heated, the outer part will crack.

- Do not bring the fireplace to a maximum temperature.

- Ensure a safe distance between the fireplace and objects that are highly flammable (at least 65-70 cm).

- Systematically clean the fireplace from ash and soot.

- total area of the room

- feature of the installation location

- chimney outlet (through the wall or through the roof).

- It should be shallow and at the same time wide. Then the heat transfer area will be maximum.

- To increase thermal efficiency, various elements are added to the design of wood fireplaces: heat shields, air cover, etc. When heated, they give additional heat.

- The masonry of the fireplace does not have to be flat. Some bricks may protrude - this does not affect the heat transfer.

- To increase the efficiency of heat transfer, it is not recommended to perform too massive a facing layer.

- Layout on the floor size under the fireplace.

- Removing part of the floor covering according to the size of the fireplace.

- Digging to the depth of freezing. Usually it is 60-70 cm. Use a bayonet shovel for these works.

- From old boards or plywood, we create the formwork, which is a wooden frame. Fasten with nails or screws.

- Waterproofing formwork. To do this, lay a layer of roofing material around the perimeter of the formwork.

- Attach a reflective foil screen to the wall using self-tapping screws. The size of such a screen is 1 * 2 meters. In this case, consider the size of your fireplace, the top of the screen should go beyond the highest point of the fireplace by 30 cm.

- Using ceramic tiles, you can create a beautiful protective screen that fits perfectly into the overall interior of the room and emphasizes the beauty of the fireplace.

- 1 row is laid out solid, according to the ordering scheme. The size of the base will be 90 * 90 cm. Using the building level, check diagonally how smoothly you have laid the bricks. The first row has a rectangular shape.

- The 2nd row is also laid out solid, but already lays the angular shape of the structure. Please note that its 2 sides are 89 * 89 cm. Watch the thickness of the seams.

- Take a small amount of small firewood or brushwood and put in the combustion chamber.

- Do not immediately give a strong heat to the oven; warm up gradually.

- Unlike built-in options, you can install in an already built house,

- You can heat several rooms at the same time: the room in which the fireplace is installed, and the room, against which it also leans against the wall,

- The usable area is spent rationally. The fireplace is a fairly large part of the interior, which can be difficult to find a place to install. The angular arrangement of the furnace and chimney in an empty corner allows you to save valuable space.

Chimney

Through this structural element, combustion products are removed. It can be made of brick or steel. In stores, you can also find ready-made ceramic structures that are assembled from individual parts.

Conclusion chimney over the roof

When constructing a chimney of a wood fireplace, it is very important to adhere to basic fire safety measures and to properly insulate the places where the pipe passes through the wall and roof.

Stove stoves classify chimneys into three types:

If a chimney is laid inside a major wall or structure, it is called a wall. It is as if it is a single unit with a wall ceiling.

But the main chimney is a separate element, which is separate from the fireplace (stove). It is connected to the main structure using a flip sleeve. Depending on the number of stoves and fireplaces connected in the main chimney, there may be several such hoses.

Chimney root pipe

Thus, the root (remote) pipe is the core for the output of combustion products, and such a system is often used precisely in large houses with many rooms. This allows you to implement several fireplaces in the house and not violate the aesthetics of the exterior of the house. Indeed, in this case, the exit of the chimney through the roof will be only one.

The flip-flop sleeve connected to the remote pipe is made of red brick, on which a steel case is put on. The length of one sleeve should not exceed 2 meters, otherwise there may be problems with traction, and the effectiveness of the fireplace will decrease.

To clean the sleeve from soot, a special cleaning door is performed. And in order to maximize traction in the flip sleeve, it is raised by 10 0 in the direction of gas movement.

The same point must be taken into account when constructing pipes for the passage of the chimney through the wall.

If the fireplace is located in a place where it is not possible to bring out a vertical chimney, then the only right decision would be to build a chimney with an exit through the wall to the street.

At the same time, horizontal sections should be minimal, and to maintain good traction, they are also raised at an angle of 10 0.

But it is impossible to lay a pipe in the attic, as condensation may occur due to the large difference in temperature, which will increase fire hazard.

The nozzle pipe is most often used by stovepipers in the construction of fireplaces. She rests on the fireplace array. But in order for the stove (fireplace) to withstand the load of the chimney, the thickness of the walls of the stove must be at least ½ brick or more.

The minimum cross-section of the pipe is ½ * ½ of the brick.

Another key element of the chimney is flue. This is the expansion of the chimney in the place where it passes through the attic floor.

Why is it necessary to expand the pipe in this place?

This will protect the wooden ceilings from overheating. To do this, the lining is laid out in the thickness of one brick (1.5 bricks are also possible) and is additionally insulated with asbestos felt or a sheet saturated with clay mortar.

The entire space between the attic floor and the grooves must be filled with fireproof material (concrete).

The pipe that passes through the attic floor is called a riser.

There is another important element in the design of the chimney, which is called the otter. This is a small expansion of the pipe when discharged through the roof. The purpose of the otter is to protect the attic from atmospheric precipitation.

Fire safety measures when laying a corner fireplace

The foundation is being built separately

The weight of the brick fireplace exceeds 1 ton, and if during the shrinkage the main foundation of the house sags, this should not affect the design of the fireplace. Otherwise, it may deform and gas will penetrate the room.

Basic rules for laying a corner wood fireplace

As for fire safety during the operation of the fireplace, here you also need to adhere to certain rules:

In order for the fireplace to warm up the room well, it is necessary to correctly calculate its dimensions before the construction stage.

Its dimensions are affected by:

Features of corner fireplaces

Among the many types of designs of fireplaces, the corner fireplace took one of the first positions. Such a fireplace looks very stylish in the interior and at the same time saves space.

The corner fireplace allows you to create a unique atmosphere of warmth in the house and emphasize the individual style.

They are distinguished by compactness, thermal efficiency and a neat appearance.

Often this form of fireplace is used for zoning a room, especially if it has a large area.

Due to its shape, the corner fireplace fits perfectly into the design of absolutely any interior. The undoubted advantage of the angular design is ease of installation and originality.

In order for the corner wood fireplace to be as effective as possible, it is necessary to take into account the following features during construction.

Open hearth fireplace

But no matter how big, massive and stylish the corner wood-burning fireplace turns out, do not forget that it, first of all, performs a decorative function. Therefore, to use it as the main source of heat does not work.

Corner fireplace with a cast iron firebox

If the cottage or house is located in the northern or eastern part of the country, then you can not do without a good heating system.

According to the design decision, corner fireplaces can be decorated in:

The classic corner fireplace in the English style is made in the form of the shape of the letter "P". For cladding, ceramic tiles or red bricks are usually used.

But for country, as a rule, choose the shape of the letter "D". At the top of the structure is a wooden beam.

Art Nouveau style is distinguished by more flowing forms. This option fits perfectly into any room.

We draw the project of a corner fireplace

Before proceeding with the construction of a corner fireplace in the house, it is necessary to draw up a detailed project and complete the drawing. The drawing should reflect all structural elements, affixed dimensions.

If you want to increase the size of the fireplace, immediately calculate how much additional material it will take and what kind of power the fireplace will produce.

Below we give a masonry scheme where the warping of the combustion chamber starts from the sixth row. You can slightly change this design, depending on the purpose of the fireplace and personal preferences.

If the main task of the corner fireplace is to heat the room, then the firebox must be done low so that the floor warms up well, taking cold air from below.

If the main purpose of the fireplace is a decorative function, then you can raise the firebox above the floor

We calculate the size of the combustion chamber

The dimensions of the fireplace will depend on the size of the room, so below we give a table that will tell you how to correctly calculate the dimensions of the structure.

The area of the room must be divided by 50.

The correct proportions of the fireplace insert

This value will prompt how much the opening of the combustion chamber should be.

For example, for a medium-sized room (20-25 square meters), you need to make a fireplace with a firebox 0.5 m 2 wide.

As for the overall dimensions of the structure, the ratio of width and height 3: 2 is ideal.

As mentioned above, the depth of the firebox is of great importance. The heating efficiency will directly depend on it. Keep the following proportions approximately: firebox depth = ½ or 2/3 of the height of the firebox.

The size of the fireplace must be maintained in a certain proportion

If for the sake of decorative purposes you decide to increase the volume and depth of the combustion chamber, then keep in mind that this will significantly reduce the efficiency of heating the room.

We calculate the size of the chimney

It is equally important to correctly calculate the size of the chimney, since the draft will directly depend on this.

The optimal ratio is the pipe cross-section in the amount of 1/10 of the entrance area of the combustion chamber.

If the chimney has a circular cross-section (for example, if you use a pipe sandwich for the construction of the chimney), then take a diameter of not less than 150 mm.

The location of the chimney on the roof relative to the ridge

With a smaller diameter, thrust will be significantly reduced.

The height of the chimney must be at least 5 meters. But if the house is on 2-3 floors, then it will, of course, have to be raised. Here it will be necessary to focus on the position of the roof ridge.

Below are certain patterns of the outlet of the chimney, which are focused on the position of the roof ridge.

Foundation construction

Given the massiveness of the angular structure, it is necessary to make a separate foundation for the fireplace.

The order of work is as follows:

Protecting walls from heat

Given the angular design of the fireplace and the tight fit to the wall, it is necessary to perform a number of fire-fighting actions to protect the walls from overheating.

There are two ways to do this:

If the clean floor comes close to the fireplace, then it is recommended to lay 15-20 cm of protective coating in the form of ceramic tiles before the base of the furnace.

Preparation of materials for masonry

Given the complex angular design of the fireplace, you will need a large number of hewn and divided bricks into ½ or ¼ parts.

How to do it right?

It is better to divide the bricks immediately, according to the order. Before separating the necessary part of the brick, mark the marker with a marker on its front side and make a groove.

Squeezing brick at the right angle

At the same time, for ½ brick, one longitudinal groove is enough. In order to break off 1/6 or 1/8 of the brick, the groove is carried out on all sides of the brick.

Before starting the masonry, lower, select the entire brick with which you will work at this stage and lower it into water so that it collects moisture as much as possible.

Masonry brick must be soaked in water before starting work

If you put a dry brick, then it will begin to gain moisture from the masonry mortar, which can adversely affect the strength of the masonry.

Tip. Do not rush to immediately clean up the fireplace. First, disassemble the order and lay out each row “dry.” Number the brick of each row and arrange it in groups on the floor. So you can see all the difficult places that you have to face, and avoid serious errors, which then will be difficult to fix.

Masonry fireplace

Before you lay the foundation, measure the sheet of roofing material and lay on the floor. It will perform the function of waterproofing.

Advice! To make perfectly even seams, take wooden slats equal in thickness to the thickness of the seam. Lay a brick, and on top of the rail. Apply the solution and lay the second row. When it dries, remove the rail. Prepare the number of rails so that they are enough for 2 rows. By the time you finish the third row, you can get the wooden fixture from the first row and use it further.

Advice! To prevent the stove from laying away when laying, pull 4 plumb threads that fasten to the ceiling. They will serve as peculiar beacons for the furnace.

Pay attention to the shape of the bricks, they are all of different shapes. At the preparatory stage, you should have already divided them into appropriate fragments, laid them “dry” and numbered each.

- 3 row we begin to form a niche for firewood, located under the hearth of the fireplace.

4 row with corner

Please note that fireclay bricks in this series are also not completely whole. It will first need to be prepared. 7 row begins to form a firebox. The walls of the firebox are laid out with fireclay bricks. Do not forget that between ordinary and heat-resistant bricks you need to leave a gap of 3-4 mm.

Please note that fireclay bricks in this series are also not completely whole. It will first need to be prepared. 7 row begins to form a firebox. The walls of the firebox are laid out with fireclay bricks. Do not forget that between ordinary and heat-resistant bricks you need to leave a gap of 3-4 mm.

11 row tooth formation

We grind the central corner brick, as shown in the figure. He is draining inward.

Bricks will go to this row - 11 and 1⁄2 (red), 5 (fireclay). 18 row. Again, we increase the size of the side walls by 30 mm, and we cut the front part, as in the previous row, from the bottom.

To do this, the bricks forming the back wall are released inward by 60 mm and cut from the bottom obliquely at an angle of 450 21 rows. The size of the chimney is brought to 130 mm. The brick of the back wall extends forward to obtain this distance and is cut from below to the size of the previous row.

Facing work

The final stage in the form of cladding carries not only a decorative function. The lining layer facilitates the care of the fireplace, there is no need for constant painting of the plaster, etc.

If you bought a beautiful red brick, then initially you can make a fireplace "for the layout." The fireplace in the classical style will become a very beautiful decorative element in the living room, in a wooden house.

High-quality cladding will perform a protective function, increasing the strength of the entire structure. As a facing layer, you can use artificial stone, ceramic tiles - it all depends on personal preferences and the style of the interior.

Fireplace

If you chose artificial stone as the cladding, then you will need a special glue mixture designed for high temperatures.

You can use the same solution that you used when laying the fireplace. Remove excess solution immediately, otherwise it will be difficult to clean the surface of the stone later.

Plastering with subsequent painting is a very economical and uncomplicated option that will allow you to realize beautiful decorative elements. The advantage of this option will be ease of use, and the paint, if desired, can always be refreshed or changed.

The only drawback of this option will be the sensitivity of the plaster surface to impacts, so it’s better to lay out the corners of the fireplace with a brick or artificial stone.

To increase safety measures during operation, you can install a protective screen on the fireplace.

You can buy such a screen already in the finished form in the store, or do it yourself.

A decorative protective grill protects the floor from sparks. The easiest way is to make a steel frame of two pieces of steel pipe, which are interconnected in the form of the letter "T".

Such a screen should cover about 60-70% of the focus. Positioning the screen at such a height will perform a protective function, but it will not interfere with the tossing of logs into the furnace.

The lower part of the screen is fixed to the stand, which prevents falling and swaying.

As the screen itself, you can use heat-resistant glass or non-combustible material.

Fireplace kindling

When all the facing works are completed, and the chimney system is completely completed, we proceed to the first kindling of the fireplace. It is better to wait a few days until all the adhesive and cement mortars dry well.

If you clearly follow the above step-by-step instructions and do not break the order, you will get a wonderful corner fireplace.

Open fireplace

You will literally become the creator of the home. Places where the whole family will gather for a cup of fragrant tea, share news and relax. And flickering flames in an open fireplace and measured crackling of firewood will create a unique atmosphere of home comfort.

Corner fireplaces

Fireplace - the embodiment of comfort, coziness and prosperity. People who want to put this luxurious decoration in their home often choose models of corner fireplaces. This is due to their compactness, ease of use and attractiveness.

Corner fireplaces look very impressive. However, they do not clutter up the space. On the contrary, they allow you to create a cozy corner, a secluded place to relax, in which you can relax while looking at the friendly game of flame.

Corner fireplaces are produced by various companies. In the Heatsystems online store you can buy products from German, Italian, Spanish, Polish and Russian masters. The catalog includes fireplaces and stoves made of natural stone and metal, glass and ceramics, equipped with modern fireboxes.

Design features of corner fireplaces

Corner fireplaces, unlike standard frontal "wall" models, have not only a rectangular, but also a triangular shape. The chimney of such fireplaces is also located in the corner, which allows you to significantly save and efficiently use the space of the rooms.

As for the manufacture of a corner fireplace, it differs little from the production of a traditional version. Ready-made heating systems are equipped with chimneys, furnaces, chimneys and chimney portals. The main difference is the form.

You can choose a model of a furnace for a fireplace made of cast iron, which is characterized by comparative lightness and compactness, which does not imply the construction of a separate foundation, or purchase a luxurious fireplace made of Italian-made marble with additional shelves and banquets. Heatsystems offers wood-burning corner fireplaces and alternative fuel stoves.

It doesn’t matter whether your fireplace stands in the corner or in the middle of the room; in any case, it will create a unique atmosphere of comfort in the house. The main thing is that it be installed in accordance with safety standards. Heatsystems specialists not only sell, but also install corner fireplaces.

Assortment and technical advantages

We offer corner fireplaces from leading manufacturers in France, Belgium, Russia, Poland, Spain and other countries of the world. Models vary in price, size and design. But they all have a number of characteristic advantages:

On all issues of the selection, use and installation of equipment, detailed consultations are provided.

Material selection

The fireplace, the cottage with which is guaranteed to receive a high-quality and efficiently working source of heating and heating, can be assembled and lined with various materials. Mostly, the construction is made of high-quality red brick or more expensive clay fireclay, which is also called stove.

The fireplace, for which the brick is chosen correctly, will quickly heat up and also cool down quickly. Heating with such a furnace continues only at the moment of burning in the firebox. The design itself consists of a furnace compartment, a fireplace portal and a chimney. The firebox itself can be open or closed. For closed furnaces, the chimney is partially built into the wall and mounted even at the stage of building a house. Open structures on the contrary, can be erected at the stage of repair work. The chimney in this case will be placed near the wall.

The most effective is a cast iron fireplace. It has high power and, due to the built-in grille, is able not only to generate heat, but also to transfer it to the room. Thus, the heating will be carried out not only evenly, but also gently enough, without overdrying the air in the room.

Steel or metal fireplace has a small mass, which allows you to place it in any room, without reinforcing floors and building an additional foundation. Metal fireplace inserts heat up several times faster than cast iron, but are less durable and do not retain heat at the end of the furnace, unlike the first ones.

Combustion chamber and design

The fireplace is wood, the price of which depends on the order or the chosen model has a firebox. The firebox may be open. In this case, you can easily cook in such a hearth various dishes, vegetables and meat. Also in this variation, the fire is maximally open, which allows them to admire at any time. Open fireboxes go well with any interior and look very impressive.

Closed fireplace inserts are safer and are installed in houses in which there are animals and children. Closed fireplaces are equipped with a steel door or refractory transparent glass, which allows you to control the level and intensity of the flame without opening. Closed models are more efficient in terms of heating. They are able to accumulate and gradually give off heat to the room. Also, due to the limited supply of oxygen to the furnace compartment, the combustion of firewood is less intense, which in turn makes the device quite economical.

After you have chosen a place to place a corner fireplace in the house, you have chosen the appropriate order or finished cast-iron or steel firebox, you need to choose the correct design and facing of the fireplace portal. It is important that the design and decoration of the object is favorably combined with the interior of the living room or any other room.

As facing materials, you can use wood, decorative plaster, simple or decorative bricks, ceramic tiles, porcelain stoneware, tiles, fire-resistant glass, majolica, natural or artificial minerals.

Also, when designing or buying a fireplace portal, pay attention to its shape and shape. The fireplace, the house with which will be decorated in a classic style, is most often faced with wood, marble or any other natural stone. In its form, such a frame is made in the form of the letter P.

Country and loft styles are characterized by a different design and portal shape in the form of the letter D. The country fireplace has a massive shelf located in the upper part of the structure directly above the furnace compartment. As a facing artificial or natural stone is used.

If you prefer modern variations, we recommend building a heating unit in the Art Nouveau style. It will be characterized by the presence of smooth lines and bends. No less popular are high-tech fireboxes for cladding and manufacturing of which mosaic, steel, cast iron, glossy plain tiles, mirrors, reflective surfaces and fireproof glass, non-combustible plastic are used.

Fireplace, brick for which is the basis of the portal and the furnace may not be lined with other materials. To give such a surface a more well-groomed and attractive appearance, you can process the bricks with a special varnish composition, grind and make seams.

After you have decided on the place of installation of the device, the room, design features, dimensions, shape, type of firebox, materials and cladding, you will need to create a detailed and subtle scheme for the realization of what was intended.

The ordering shows what dimensions the heating unit has, in which place this or that element is located. With it, you can pre-determine and calculate with maximum accuracy how many building materials, mortar and accessories are needed.

Also, when drawing up the order, it is important to take as a basis the design features of the furnaces. The installation will consist of a portal, an open or closed combustion chamber, which passes into the chimney, which should be knee-shaped. Thus, soot and sparks will not go out into the room, which will protect your home from accidental fire.

If you do not install a chimney in a special sump mine, you will need to equip it with caps that allow all gases and combustion products to accumulate. Ash and other accumulations are easily cleaned and eliminated if the design of the heating unit provides for the presence of a grate or ash chamber. In order for air to enter the furnace in the required amount, the design is equipped with a blower.

The efficiency of the brick structure is always very small and equal to 10-20 percent, which is not enough for proper heating of the house. In this case, many stove-makers go to small tricks and supplement the furnace with certain elements. It is possible to equip the furnace with a cast-iron or steel door, a shield. It is also possible to equip the installation with a collector that will allow the heated air masses not to be taken out directly to the street, but to circulate in the firebox and to some extent go out into the room.

Fireplaces equipped with a secondary afterburner and a long burning function, which allows firewood not only to burn, but also to smolder, are very popular. Also, for heating a large house, you can use the fireplace stove with a water circuit, in which water circulates through pipes and radiators.

If you approach the process of buying or erecting a fireplace in a house, in a country house or in an apartment with all care, responsibility and taking into account all the rules and recommendations that are described in this article, at the output you will get a fairly powerful, efficient and stylish heating device that can heat your home and will delight you with its attractive appearance for many years!

In this video you can get acquainted with how to assemble a brick corner fireplace for a wooden house, for a summer house with your own hands: