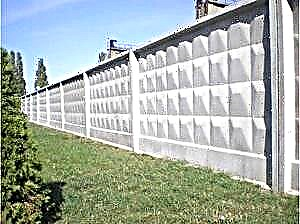

Concrete fences are a prefabricated structure divided into sections. The device fencing of the site by installing a concrete fence can be called a rational and practical solution in ensuring the protection of their territory from the visit of uninvited guests.

Ready Mounted Concrete Fence

Technological features of the installation

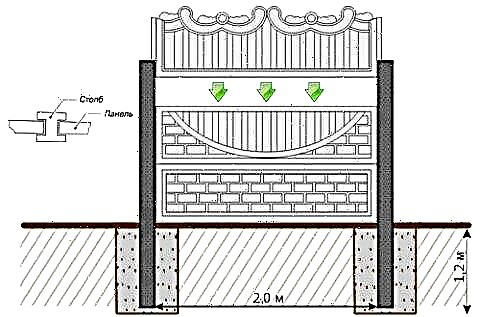

The concrete fence design can be fixed to special supports or installed separately. Separate fences are arranged not only from reinforced concrete slabs, but also special glasses that perform the function of the base. The construction of the fence, implying the use of glasses, is not difficult: racks with panels are installed in a glass and poured with concrete.

If there is no need for a permanent fence, then the racks can simply be fixed with wooden wedges. The construction of a fence made of reinforced concrete slabs cannot be called such a difficult task.

Tools and materials

To install a fence of reinforced concrete slabs, such materials and devices will be required:

- Shovel and crowbar

- Level and optical level,

- Reiki made of wood,

- Cord or rope

- Materials: crushed stone, cement, sand,

- Hard wire

- Primer and facade paint,

- Concrete mixer (can be replaced with a construction mixer or drill with an appropriate nozzle).

It is also necessary to invite someone from friends or relatives to help with work.

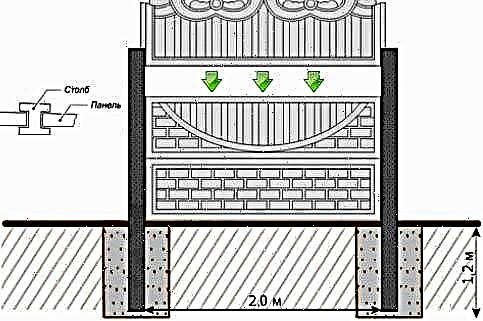

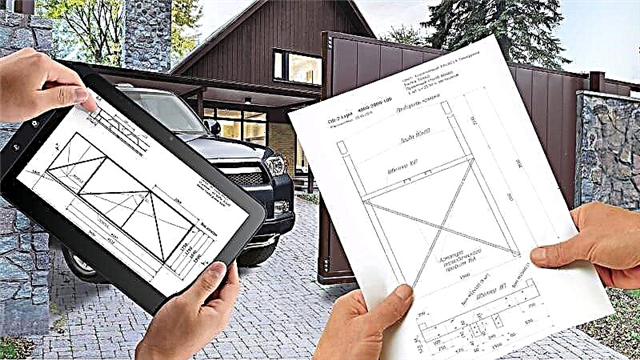

Drawing pillar and concrete slab for installation

Preparatory work

Before starting the main work, it is necessary to thoroughly prepare for them. First of all, it is necessary to prepare and collect all the necessary tools and materials, check their operability and the required quantity. First, determine the exact location of the future concrete fence.

To do this, with the help of a tape measure, wooden stakes and a cord, the perimeter of the fence is planned, the installation sites of the poles are determined, all the deferred distances must be carefully checked again.

It is recommended to install the supports every 2–2.5 meters, having previously hammered wooden pegs into these places. You should also prepare in advance the pits in which the posts will be installed, if during the construction of the concrete fence it was decided to abandon the foundation.

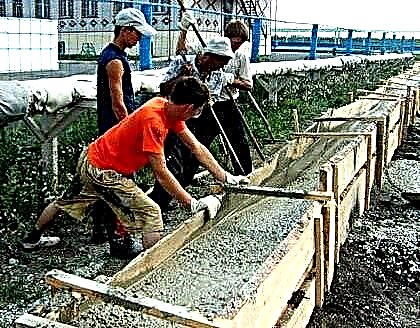

Pouring a monolithic foundation for the subsequent installation of a concrete fence

Installation of supports

In those places where it is planned to install the fence with your own hands, you need to stretch the cord at a height of about half a meter from the surface of the earth. Thus, the perimeter of the future fence is clearly marked, and the resulting lines will not allow you to deviate in one direction or another in the process.

In the grooves prepared in advance for the installation of pillars, it is necessary to arrange a special pillow consisting of crushed stone or gravel and sand. The pillow contributes to the reliable installation of the supports in the pit and ensures the removal of moisture during operation.

Further, on a gravel-sand cushion, it is necessary to place the pillars, establish their even position relative to each other using a level and securely fix them in the ground.

When installing the pillars, their fastening in the pit can be done by adding stones, cracked brick, concrete waste into it. Filling the pit must be carried out approximately to the middle of its depth.

In the groove of the support prepared in this way, a long rail should be laid corresponding to the length of the concrete slabs that make up the fence wall. This is done in order to control the correct placement of the supports. You should also make sure that the supports "looked" with their grooves in the direction of the rails. To control that all supports are level, a hydraulic level should be placed on the rail.

If it seems that at some stage a mistake has been made and the supports are uneven, you will either have to deepen one of the holes that has the pillar, or add soil to it, thereby reducing its depth.

On the upper part of the concrete supports, it is necessary to fix a wire or cord, and put an additional wooden rail in the grooves, which will allow to maintain the required interval between the supports with greater accuracy.

Each support should be set strictly according to the level, for which it will be necessary to use the level again, and finally fix them in the holes. Wooden slats should not be removed so far, before laying the plates they should be placed at their ends in the grooves of adjacent supports.

After all the supports are finally installed and secured, it is necessary to prepare a cement-sand mortar with a creamy consistency based on a ratio of 1 to 4. After that, it is necessary to once again check whether the entire fence structure is installed evenly and pour the remaining part of the pits in which the supports are installed .

After filling in all the pits, it is necessary to check for the last time the location of all the pillars by means of a hydraulic level, since during the filling of the pits with a solution, a deviation of the position of the posts quite noticeable even to the naked eye can occur under the influence of the weight of the solution. All inaccuracies and errors, even very small, should be immediately eliminated, without waiting for the solution to solidify.

Installation of supports on the foundation

If it was decided to install it on a strip foundation when erecting a concrete fence with concrete, then some changes need to be made to the installation technology. When digging holes for supports, it is also necessary to arrange a trench for the foundation in parallel. The depth of the trench should be taken the same as for the pits, but the width is a little less.

After preparing the trench, you need to build a wooden formwork of the required size. In order to save time and effort, as well as slightly reduce the final cost of fencing, it is recommended that the formwork be made for one span, and then transferred to the next site of work.

At the bottom of the trench, a sand and gravel cushion is arranged, reinforcement is installed and the body of the future foundation is filled with a solution of the same proportion and consistency that was adopted for filling the pits.

Preparation of pillars for pouring the foundation

Installation of reinforced concrete panels

Upon completion of the installation of pillar supports and their reliable fixing in the pits with a solution, you can proceed to install reinforced concrete panels with your own hands. If the work is done in the summer, then you can start the installation the next day after installing the columns. In spring and autumn, you should wait a few days.

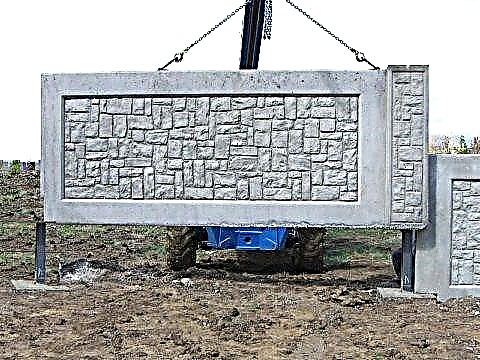

Installation of plates is simple: they are inserted from top to bottom in the spans, gliding along the special grooves available in the supports. During this work, it is necessary to carefully monitor the uniform filling of empty spans. When doing this work, you can’t do without an assistant, and if the wall panels are too heavy, then a truck crane may be required.

Characteristics of concrete fences

Currently, concrete fences can have absolutely any shape. It is created thanks to special blocks or with the use of plastic substances in concrete mix.

In addition, reinforced concrete structures are able to provide reliability for many years and simple operating rules. Caring for them is simple and everyone will cope with it, there is also the possibility of coloring with decorative compositions of the resulting fence.

The advantages of this type of barriers are:

- Universality in use with a guarantee of long service.

- Ease of construction. Everyone will cope with the installation of concrete fences, if you follow the detailed instructions.

- The possibility of manufacturing a variety of forms will create a unique facade design.

- The material is easily combined with any other types of materials.

- You can design such a fence with any cladding. Suitable stone, tile, decorative clay, etc.

- The construction of such a fence can be made on any ground.

- At a price, a concrete fence is the least expensive.

Of course, the material has a lot of advantages, but there are also its drawbacks:

- Large time costs associated with waiting for each individual layer of concrete to dry.

- The possibility of erection only in warm weather.

- When using cast jewelry, their cost is quite high.

- A good result can only be obtained by calculating everything accurately.

- The yard space near the fence will be in the shade, as the structure is very dense.

Therefore, before deciding on the construction of such a fence, you need to consider everything.

Tips & Tricks

If it is necessary to give the fence a suitable color, then the surface of the panels and poles must be primed and painted with facade paint. Also, even before the installation of the fence, it is possible to purchase panels that are made of pigmented concrete, produced in various colors.

To protect the fence from the weather, it is recommended to install protective caps made of metal or concrete on top. The foundation or columns can be decorated with your own hands with various decorative elements, which, however, will increase costs and slightly increase the cost of erecting the fence structure.

Types of Concrete Fences

Concrete fences are presented by different types of execution. It:

- monolithic structures

- typesetting sections,

- self-standing fence

- decorative format

- block perimeter from concrete goods.

Each type of concrete fence has its own technical features that must be considered when choosing a model.

Advantages and disadvantages

The main advantages of a concrete fence are:

- strong structure

- rapid installation due to the presence of sections, large sizes,

- the ability to paint the product in any colors,

- durability.

Fences from concrete sections have their own disadvantages:

- they are heavy, which complicates their transportation and installation,

- in case of damage to the concrete layer, the internal reinforcement is subject to corrosion.

Features and specifications

Concrete fences are not complex structures, but they have their own characteristics. In the manufacturing process, concrete sections are created by means of vibropressing and vibrocasting. For the fence and its elements use concrete grades M250 or M300. They are characterized by a high degree of frost resistance - at the level of F50.

Each section is reinforced with a frame of welded wire mesh. They are made of high quality wire or fittings. In the production of enterprises are guided by standards 3.017-1. According to them, for the passage, the thickness of the fence is 8–16 cm with a height of 1.2–2.9 m. It is allowed to equip the entrance gates with transport passage and pedestrian gates.

When choosing a design, it is important to consider that a concrete sectional fence cannot be installed in areas with seismic hazard, which on a Richter scale exceeds 6 points.

Prefabricated reinforced concrete elements are specially marked. It encrypted product information. The first letter is the name. The following symbol indicates the size, then the height indicator. The end face of each part captures the following parameters: mass, labeling and release date.

Features specific models

The following model features:

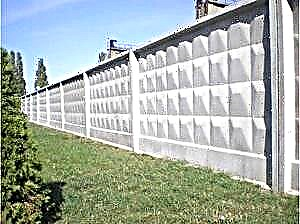

- Monolithic. These are the most durable designs. The installation of the elements of such a concrete fence is carried out on a foundation - cast, strip or column. The object consists of solid smooth slabs of reinforced concrete, but may have a specific pattern applied to the surface. It is preferable to install such a sectional fence of large sizes in industrial areas, to enclose warehouses with it.

- Block structures are assembled from concrete panels, each of which is small in size. The constituent elements are fixed with a solution. It is possible to decorate models with tiles. Installation of prefabricated elements occurs quickly on the foundation, with a width exceeding twice the width of the blocks.

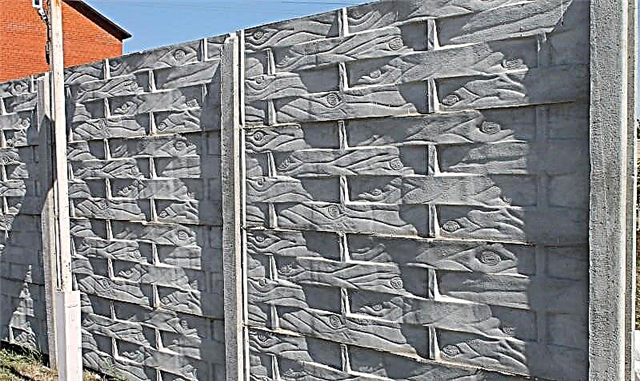

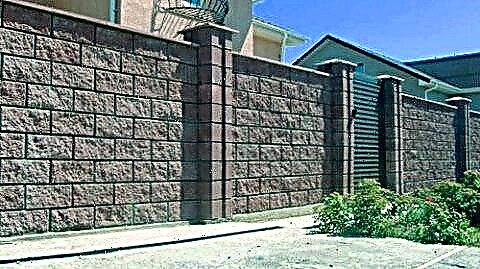

- The stacked version also consists of several concrete sections. Such reinforced concrete panels can be large in height and length. The appearance of decorative concrete fences is diverse: panels imitating stone, similar to bricks.

- Self-standing prefabricated samples are used to enclose industrial areas and construction sites. They are based on large-sized solid reinforced concrete products, which do not differ in attractiveness, but are recognized as the most durable. Installation of structures does not require a separate foundation; they are stable due to the special shape of their base.

What should be the base of the fence

Before installing a precast sectional or other type of concrete structure, it is important to choose the type of foundation that is suitable for the soil on the territory. For this purpose, it is better to attract specialists engaged in geological surveys. If the problem is solved independently, then it is worth inspecting the fencing of neighbors. In case of any flaws, subsidence of the structure or its skew, it should be concluded that there is a strong swelling of the soil. In this embodiment, it is preferable to use a columnar base. The strip foundation from the pillars will go for a marshland, where there is an excess of moisture.

Installation

Do-it-yourself fencing without mechanized assistance is not possible. The blocks of these structures are very heavy, for this reason such models are more often demanded during capital construction, when vehicles are operating at the facility.

For home use, decorative fences made of concrete are usually used. The installation plan is as follows:

- Prepare the site, mark the foundation with a building level. 5-15 cm to retreat from the border of the territory, preventing entry to the neighbors' area, extend the cord and lay pillars and panels along the planned line.

- Dig holes for poles with a distance between them of up to 2 m, a depth of 50 cm.

- Install pillars using chipped brick or crushed stone. They are mounted on the same level. To do this, you need to take a wooden rail inserted into the groove of the first structure and the next. If curvature is present, align the posts.

- Fill the holes with a sand-cement mixture.

- Re-check the fence level and, if there are deviations, correct the posts.

- Upon completion of the installation of the columns, proceed with the installation of the sections.

- The finished construction of concrete sections to make it more attractive to paint with concrete paint. To give originality to a prefabricated fence, you can apply decorative elements and facade paints.

Decorative fences

The main material for decorative reinforced concrete fences is a concrete mixture. However, when creating precisely decorative panels, special forms are used, with the help of which a variety of elegant outlines of the product are carried out.

This type of design has a different style solution, color and size range. Here, the external data of the finished sample depends on the wishes of the owner. Some manufacturers offer a service for casting fences according to individual drawings. Famous sellers of decorative concrete fences in their arsenal have over 300 types of artistic casting, shapes and colors, use wooden elements and other decorations. This allows you to satisfy any tastes.

Selection recommendations

When choosing a concrete fence, the owner is obliged to solve some issues. Here are a few criteria:

- Determine what the construction is for.If the main objective is safety, then it is better to purchase a high fence with additional security features. When it is planned to keep animals - the figure should be simple, and the height determines the type of living creature on the territory. If you want to get an aesthetic pacification, it is better to find masters who can do everything according to the original project. Although it is more expensive, but beauty requires it.

- When buying a fence, it is important to determine its type. Large-height blind enclosures are extremely rarely used in the private sector, since it is not aesthetically attractive. More such products are in demand at industrial facilities.

- If a blank fence was decorated with elegant elements, it not only protects from prying eyes, but also pleases with its aesthetic appearance. Such designs are preferred by the owners of the cottages.

- For a private local area, experts recommend products up to 1.5 m high with the obligatory presence of half-open sections and decorative drawings. This approach will make the fence beautiful and practical. When plants are planted in front of the house, it is recommended to put a low fence made of entirely half-open slabs. This will allow the vegetation to obtain the required rate of sunlight.

- A decorative concrete fence as a fence is not the best option, since such a design is low, assembled entirely from half-open panels. They are often used to enclose administrative buildings and parks.

Giving preference to any type of fence, it is important to consider that it fits into the architectural ensemble with buildings on the site.

What is a concrete fence

Concrete fencing is presented by many in no way as a picture pleasing to the eye. However, rough concrete tile panels - legacy. A great contribution is actively being made to the aesthetic appearance of such fences, which is why they look not only reliable, but also beautiful. Currently, concrete fences are in demand largely because of their decorative qualities.

Concrete fencing is presented by many in no way as a picture pleasing to the eye. However, rough concrete tile panels - legacy. A great contribution is actively being made to the aesthetic appearance of such fences, which is why they look not only reliable, but also beautiful. Currently, concrete fences are in demand largely because of their decorative qualities.

Such products are not used everywhere. For example, no one orders concrete decorative fence for an industrial zone. It is more often used as a fence for private sectors, schools and kindergartens, as well as some enterprises. It consists of separate sections.

Concrete fence sections adjust its height. They are one of its advantages, which allow adjustment without prejudice to appearance. For example, you can choose:

- One section that will be exclusively decorative. With its help, low partitions are easily constructed inside the site, but not for external fencing,

- Two sections. They are suitable for those low barriers, the purpose of which is to prevent the penetration of animals on the site,

- Three sections - this is a common, standard equipment, the elements of which are harmoniously combined with many facades and types of landscape design. They have a lot of varieties,

- Four sections, which are high and heavy fences. At the place of their construction, a foundation may be needed - this will prevent subsidence and various defects that sometimes occur over time.

Concrete fencing panels can be made with a pattern only on the street or in the yard or be decorated on both sides. All products are selected individually. If you wish, you can fence yourself off from those around you with a solid and high fence, or you can choose a light openwork fence through the patterns of which landscape design will be visible. Carved figured blocks are significantly lighter than solid blocks, and also consumes less consumables.

Advantages and disadvantages

On the aesthetic side, decorative panels of such a structure compare favorably with many other types of fences. He is not only reliable, but also ennobles the overall picture that appears against his background. According to customer reviews, panels with a double-sided pattern are especially good. Among others benefits of sectional concrete fence can distinguish:

- Quick installation, which is due to the prefabricated design of the panels,

- The combination of high quality and relatively low compared to many other cost protections,

- All installation and even production can be done with your own hands,

- Reinforced concrete structures are highly durable,

- Resistance to aggressive weather conditions - such fences are frost-resistant and are not subject to significant negative effects of moisture,

- Fire safety

- Ecological safety - a concrete fence does not pose a threat to the environment, human health or pets,

- In case of various incidents, there is no need to change or overhaul the entire structure, since it is always possible to replace damaged sections of the fence,

- A wide selection of design solutions,

- Replacing the upper sections of the fence allows you to update its appearance at any time and without significant costs,

- Long service life of about 50 years.

The operational and decorative characteristics of such facade products are quite high. Among the shortcomings, it can be distinguished that continuous sections do not let in the sun's rays, thereby slowing down the development of nearby plants and flowers. However, it is easy to find a way out of this - so that the adjacent territory is not empty, you can plant a site behind a concrete fence not with low vegetation, but with tall trees or weaving plants.

The operational and decorative characteristics of such facade products are quite high. Among the shortcomings, it can be distinguished that continuous sections do not let in the sun's rays, thereby slowing down the development of nearby plants and flowers. However, it is easy to find a way out of this - so that the adjacent territory is not empty, you can plant a site behind a concrete fence not with low vegetation, but with tall trees or weaving plants.

Decorative views of the fence

Currently, sections are widely used that successfully imitate various other surfaces that do not look like concrete. Considering that concrete sections are decorated not only from the outside, but also from the inside, most imitations look believable. At the same time, the upper part of the fence is often formed by a curved decorative section.

Currently, sections are widely used that successfully imitate various other surfaces that do not look like concrete. Considering that concrete sections are decorated not only from the outside, but also from the inside, most imitations look believable. At the same time, the upper part of the fence is often formed by a curved decorative section.

Longitudinal seams between sections are also well hidden. To do this, they try to place the seam along the uneven joints of the supposedly masonry, which results in a decorative fence, as if made of natural stone. Concrete poles cast in the form of various shapes are also subject to decoration.

The forms and their sealing panels are made of ABS plastic, on which various types of imitation, eg:

wooden plank,

wooden plank,- brickwork,

- marble,

- vines

- Chipped

- ancient mosaic

- Kremlin wall

- rope,

- rocky mountain

- lock lattice.

The technology for manufacturing concrete sections under marble is popular. Without pores and cracks, durable and at the same time glossy fences have a very attractive appearance. A special smooth and matte surface is provided by a special paint, which is applied over the entire mass of each product. At the same time, the panels do not fade in the sun, and the texture is preserved throughout the entire life cycle, without requiring additional care.

Composite options

Composite versions of products mean sections in the production of which various materials are involved. Designers also developed sections with the puzzle principle of connection, due to which it turns out to be better to hide each seam. The most common types of concrete fence panels are:

- monolithic lower smooth or with texture (under the bark of wood, natural stone, brickwork),

- openwork middle or combined with transitions (there are lattice, columnar and patterned).

They differ primarily in their appearance. There are no standards in terms of their choice - everything will depend on personal preferences and compatibility with the general background of the territory.

Panel Quality Determination

When planning the arrangement of the territory with a concrete fence, it is important to assess the quality of its structural elements. Although the concrete fence itself is reliable, but, like with any purchase, do not neglect the visual assessment. It must meet the following requirements:

The brand of cement from which concrete products are made must not be lower than M500. Visually, this is determined by the characteristic light gray color of the unpainted section. It is this color that indicates that the composition of concrete is of high quality,

The brand of cement from which concrete products are made must not be lower than M500. Visually, this is determined by the characteristic light gray color of the unpainted section. It is this color that indicates that the composition of concrete is of high quality,- The surface of high-quality sections should not have pores or cracks. Any voids are future foci of moisture that will accumulate and gradually destroy the structure,

- Of great importance is the accuracy with which the supporting posts for the fence are made. Panels, although they should freely enter their grooves, but not in any way pop out of them,

- The most reliable will be a fence in which concrete is combined with metal - reinforcement inside the products will give them increased strength and durability.

It is best to order a concrete fence in large companies that specialize in the production of reinforced concrete products. Even better - there you can also get a complete set of the necessary decorative elements of the same series as the panels.

Key Installation Nuances

Having prepared all the elements of the future fence, you need to dig holes for the support pillars. They are marked with a tightened rope, and each point of fixation of points for the supports is indicated by a peg. All pits dig in view of the shape of the column, in the grooves of which the panels will enter, as well as observing an equal distance from each other. The use of mechanical devices makes digging pits easier.

Having prepared all the elements of the future fence, you need to dig holes for the support pillars. They are marked with a tightened rope, and each point of fixation of points for the supports is indicated by a peg. All pits dig in view of the shape of the column, in the grooves of which the panels will enter, as well as observing an equal distance from each other. The use of mechanical devices makes digging pits easier.

For reliable digging of the support pillars, crushed stone and sand are needed - they will serve for compaction, therefore, 10 centimeters of the first and second should be laid at the bottom. Each layer is watered and carefully rammed. Concrete should be poured from the top of the holes, checking the verticality of the installation with a plumb before the mortar has time to set. Under heavy and high fences, it will be necessary to lay a solid foundation.

After all work with the supports, concrete sections are installed. The task is to think about how each plate will rise and be laid in the groove. In the case of lightweight openwork panels, the efforts of two people will be enough, while a crane is needed to lift heavy solid blocks.

After all work with the supports, concrete sections are installed. The task is to think about how each plate will rise and be laid in the groove. In the case of lightweight openwork panels, the efforts of two people will be enough, while a crane is needed to lift heavy solid blocks.

After completing all the work, you should check the vertical and horizontal structures and eliminate possible defects, after which the fence can be painted with facade paint or whitened if necessary. It is better to choose a special paint for concrete, having previously cleaned it from dirt and covering the surface of the fence with a primer. Simplicity in this case differs by a spray gun, but if you need to paint over some individual details, it is better to give preference to a roller or brush.

Additional tips

After getting acquainted with the advantages, disadvantages and main working moments of installing concrete fences, it makes sense to pay attention to the advice from designers and craftsmen, who often have to deal with them. Among their recommendations are the following:

It is possible to do without the costly production of decorative concrete fence in areas that overlook the economic part of the courtyard, go along the blank walls and high thickets. In such areas, it is advisable to limit ourselves to conventional panels without patterns, but it is important to maintain the dimensions and the distance between the support columns.

It is possible to do without the costly production of decorative concrete fence in areas that overlook the economic part of the courtyard, go along the blank walls and high thickets. In such areas, it is advisable to limit ourselves to conventional panels without patterns, but it is important to maintain the dimensions and the distance between the support columns.- To improve the appearance of smooth panels without drawings, you can hang flowerpots with ampelous forms of flowers on them. An alternative to this method can be the planting of decorative climbing plants in areas adjacent to such unpretentious fences,

- If you install a fence around the entire perimeter of the territory is unprofitable, then you can limit yourself to the facade facing the street. For the remaining length of the land, it is easy to install columns under the netting, pulling which you can be sure that it will stand for many years. Decorating it is more difficult, but weaving vegetation can help. However, much in this matter already depends on each specific site, so it is better to think through everything in advance so that there are no difficulties with buying a full set of concrete products. Otherwise, you can contact the designer,

- Care should be taken for heat-loving and demanding sunlight plants that grow along a future concrete fence. To ensure their full development - it’s better to choose a low openwork fence,

When priming the fence before painting, pay attention to the surface pattern. If it is, then after coating the panels with a primer using a roller, it is better to additionally process the textured elements with a brush,

When priming the fence before painting, pay attention to the surface pattern. If it is, then after coating the panels with a primer using a roller, it is better to additionally process the textured elements with a brush,- It is best to paint in cloudy weather and with a spray gun - this will allow you to get a uniform color. Many manufacturers produce a special paint for working with concrete, which is better to give preference, as it is resistant to sunlight and humidity. In working with the facade, all this is of great importance: any temperature differences can affect the result.

With a competent approach and following all the recommendations, you can build a concrete fence, which will give the site the appearance of a fortress. It will attract admiring glances and at the same time ward off attacks on private property by uninvited guests.

Overview of types of structures and their installation

There are several types of concrete fences, these are:

However, this classification is not complete. Each of these species has its own subspecies, depending on the production technology, design, purpose, installation method. Let us briefly consider the characteristics and installation features of structures of each type.

Monolithic construction of fences

This type is the most durable of all. It also has a fairly high weight, which directly affects the features of its installation.

If we talk about ready-made monolithic sections, then the main prerequisite for this is the installation of a strip or column foundation, without which some other types of concrete structures can do without.

Installation of such plates begins with the foundation.

If the base is tape, then the procedure is as follows:

- First of all, they dig a trench and install the formwork. It must be absolutely smooth, since any deviations can result in a tilt of the fence, that is, it can stand unevenly. The trench, depending on the type of soil, should reach a depth of 60 to 100 cm.

- To further strengthen the structure, lay out the reinforcement.

- Next, they proceed to pouring concrete on the ground part.

If you decide to build a columnar foundation, then a brief instruction on its structure looks like this:

- First, wells are made at a distance of about 1.5-2 meters and a depth of about 1 meter around the entire perimeter of the site. A small amount of rubble or sand is covered in them.

- Next, asbestos-cement pipes are installed into which concrete is poured. Outside they are sprinkled with rubble.

Note! For better fixation, the pipes are slightly raised after pouring in order to spread concrete. Then put in place and crushed. The result is a sort of foundation for the pillars on which they stand. Next, make the necessary reinforcement and dosing.

In addition to asbestos-cement columns, concrete supports for the fence can also be used. They are mounted on the same principle. After finishing their installation, you should proceed with the installation of the plates themselves. Use a specialized fastener or cement mortar at the junction.

Monolithic concrete products cannot be installed independently. Firstly, they have a very large weight, and secondly, the installation of this design requires professionalism.It is necessary to attract construction equipment.

It is also worth paying attention to the monolithic fence, which is cast directly on the site using formwork. At the same time, the installation method is the simplest, since preliminary pouring of the foundation is not required.

Start work by fixing the support pillars. Again, they drill wells with a diameter of 0.2 meters and a depth of at least 1 meter into which pipes are installed on a plumb line. Following wells are concreted.

Between the pillars around the perimeter, deepenings are made, which are covered with gravel or sand. Fittings are sometimes welded to pipes along the entire length to ensure the strength of the fence sections. Subsequently, formwork is installed under the fence and poured with concrete.

Note! After pouring, it is necessary to compact the concrete by bayonet.

The final stage is the decoration of the fence.

Euro fence concept

In fact, this type of fence is the same concrete fence, characterized by high external qualities and some production features.

Concrete euro-fences are widespread precisely due to the variety of colors and shapes. The consumer can choose for himself a diverse texture, for example, under a stone or brick. Combined options with natural stone or metal decorations are also available. They consist of support columns, which act as connecting elements with concrete panels or sections.

Eurofences are of two types: unilateral and bilateral. As the name implies, unilateral fences have a pattern or texture only from the face.

This option is very relevant when the appearance of the reverse side is not so important. Bilateral concrete eurofences are decorated on both sides. Most often, the thickness of the structure due to this increases slightly.

A significant disadvantage of them is a rather high price. Such a fence may cost less than a brick fence, however, if we compare the standard types of undecorated concrete fences, the euro fence loses in this respect.

Installation is extremely simple, which allows you to assemble a fence with your own hands. First, they mark the territory and dig in the pillars by analogy with the technology described above.

To fix heavy sections, you will need a strip or column foundation, as well as the use of a construction crane to lift them. The final step will be the laying of plates in the grooves of the posts.

Varieties of concrete fences

Concrete hedges can be different not only in appearance, but also in the method of assembly. For example, a fence consisting of ready-made slabs or a sectional concrete fence is considered quite convenient.

For the construction of the first, you will need to install pillars with grooves for mounting. Two people are free to cope with the installation of individual plates. In addition, many versions will appeal to many, as they imitate natural materials.

Monolithic reinforced concrete fences are the most durable structures for fences. It uses solid plates, which are installed using special equipment. Basically, this type of construction is used for large areas. Country houses on several floors for good protection are fenced precisely with reinforced concrete slabs.

Block type concrete fence is perfect for self-assembly. Small blocks with voids or monolithic are used for it. This option is similar to the assembly of brickwork. It is considered the most simple and not expensive.

Concrete Fence Decoration

Decorative concrete fence in our time is not uncommon. A fairly popular type of decoration of concrete fences is the manufacture of them under natural materials.

Imitation of wood or natural stone looks expensive and beautiful. At the same time, in fact, the cost is democratic. From above, this design is complemented by openwork patterns or simply even tiles.

There are also other decor options. For example, embedding special blocks with patterns or columns in the fence. You can also make cladding using decorative artificial stone or ceramic tiles.

Some simply paint concrete structures in the color that they like. For painting, most often all shades of brown, burgundy, green, blue, etc. are selected.

If there are decorative elements, they can be highlighted in white. It will look good in combination with any background. And sometimes they combine several shades of the same color, for example, brown and sand. Thus, on concrete you can realize any fantasies and preferences.

Installation of independent structures, fixing plates on glasses

When installing self-contained fences, a foundation device is not required - due to the presence of a sufficiently wide base, due to which the slabs take a vertical position.

Installation is as follows:

- First, a shallow trench is dug around the entire perimeter of the site. The depth should be about 10-15 cm, and the width should be about 20-25 cm more than the base of the plate,

- Next, a pillow is made of sand and gravel, which is carefully tamped,

- With a construction crane, the slabs are exposed.

It would be worth mentioning another option for the installation of concrete slabs, which does not require a foundation. In accordance with it, specialized concrete glasses for the fence are placed in the ground, which hold the slabs in the right position after they are fixed on the spikes.

The above process includes the following steps:

- They start work with marking the territory, pulling a building thread around the perimeter,

- The next step will be to install the glasses at a distance necessary for further fixing the plates (depends on the size of the plate),

- Using construction equipment, the plates are mounted in the grooves of the glasses.

Note! Before installation, in order to avoid deformation of the plates, choppers are installed between the products. After completion of work, they are removed.

As for the standard sizes, the most popular is PO-2, that is, the fence plate, with dimensions D * B - 2.5 * 3 meters.

The most relevant use of such a fence is for:

- Military units

- Industrial buildings

- Warehouse

- Construction site

- Other especially important and requiring protection zones.

At the top, such a plate can be equipped with barbed wire, in this case, it will be almost impossible to overcome the fence. For fencing private buildings, fences are usually used, having a lower height, about 1.5-2 meters. It is quite enough to protect the site from prying eyes.

Stacked Fences

They are partly decorative due to the presence of a large number of variations, textures and colors. They consist of sections interconnected and consisting of a set of plates. Usually there are 4. As a rule, the lower plates are deaf, and the upper one contains a through ornament.

Installation can be carried out both using the foundation, and without it. Several people can easily cope with it. 1 section has a weight of about 30-70 kg, such fences are quite easy to transport, and their price is much lower than that of monolithic slabs. Decorative finishes can be on one or both sides.

Note! When choosing concrete typesetting euro plates, pay attention to the appearance, the presence of chips, cracks and reinforcement, as well as - the brand of concrete.

Stacked fences are mounted by fixing the panels into the grooves of the posts. The video in this article will tell you more about the process.

Block concrete fence

This type is constructed using hollow or monolithic concrete blocks. The construction of intersectional posts is not required, but without specialized finishes you can not do. The most common options are plastering with decorative compositions and tiling with the desired texture.

The presence of a strip foundation in the construction of this type of fence is mandatory.

The construction of the fence takes place in the following order:

- First of all, they dig a trench under the foundation, which should be wider than the block. Depth is about 0.7 meters.

- When arranging a strip foundation, it is worth considering that the reinforcing bars should protrude at least 15-17 cm for subsequent dressing with vertical bars.

- Blocks stack row by row subject to obligatory dressing. The offset of the vertical seam in each subsequent row should be at least 30% of the block size.

- Decorative finishing can be done 5-7 days after the end of construction work.

Also, the erection of the fence can be performed using decorative blocks, while additional lining is not needed. The texture and color of such products may be different.

wooden plank,

wooden plank, The brand of cement from which concrete products are made must not be lower than M500. Visually, this is determined by the characteristic light gray color of the unpainted section. It is this color that indicates that the composition of concrete is of high quality,

The brand of cement from which concrete products are made must not be lower than M500. Visually, this is determined by the characteristic light gray color of the unpainted section. It is this color that indicates that the composition of concrete is of high quality, It is possible to do without the costly production of decorative concrete fence in areas that overlook the economic part of the courtyard, go along the blank walls and high thickets. In such areas, it is advisable to limit ourselves to conventional panels without patterns, but it is important to maintain the dimensions and the distance between the support columns.

It is possible to do without the costly production of decorative concrete fence in areas that overlook the economic part of the courtyard, go along the blank walls and high thickets. In such areas, it is advisable to limit ourselves to conventional panels without patterns, but it is important to maintain the dimensions and the distance between the support columns. When priming the fence before painting, pay attention to the surface pattern. If it is, then after coating the panels with a primer using a roller, it is better to additionally process the textured elements with a brush,

When priming the fence before painting, pay attention to the surface pattern. If it is, then after coating the panels with a primer using a roller, it is better to additionally process the textured elements with a brush,