Metal siding under the log is used for exterior and interior decoration. The appearance of the material is almost completely identical to natural wood.

Metal siding under a log is made by metal rolling from galvanized steel. For protection, the top layer with a pattern is coated with a polymer composition, which prevents rotting of the material and expands its operation. After installation, the appearance of this material resembles a blockhouse or “block house”.

The operational characteristics of metal siding are several times superior to those that have its analogues, made of wood, PVC, etc.

Material Features

One of the essential features of metal siding is a protective polymer coating. It almost completely eliminates the harm that can be done to its surface.

One of the essential features of metal siding is a protective polymer coating. It almost completely eliminates the harm that can be done to its surface.

Another difference of the material is that during the manufacturing process, galvanized steel with a thickness of 0.5-0.7 mm is used. This allows you to use siding under the log for the decoration of facades, arrangement of the basement of the building.

Recently, this material has been used for interior decoration of a building. Installation can be done horizontally and vertically.

Advantages and characteristics of metal siding under a log

The cost of metal siding is approximately double its vinyl counterpart, but this does not affect its demand and popularity.

The cost of metal siding is approximately double its vinyl counterpart, but this does not affect its demand and popularity.

Compared with PVC and other alternative materials, metal siding has the following advantages:

- Lifetime. The manufacturer guarantees more than 30 years of excellent material service life. For comparison, the declared operating time of the PVC profile is not more than 25 years

- Operational characteristics. The advantages also include its resistance to high temperatures, corrosion, mechanical stress, etc., the operating temperature range from -50 ° to +80

- Environmentally friendly material. When heating the surface, it does not emit toxic and poisonous substances, therefore it has a high level of environmental friendliness

Attention! For siding, almost the same material is used as for metal tiles. This explains its high resistance to mechanical damage and good performance.

The dimensions of the material are as follows: the height of the strip is 356 cm, the length is from 0.8 to 8 m. The optimum length of the strip during installation is 4 m. A longer profile can bend when loading and unloading material.

An interesting alternative to log siding can be Dolomite siding, which perfectly imitates stone. Interesting combinations of wood and stone siding are possible.

An interesting alternative to log siding can be Dolomite siding, which perfectly imitates stone. Interesting combinations of wood and stone siding are possible.

When choosing a siding for cladding the facade, be sure to study the options of Holzplast siding, the description and characteristics of which can be found in this article. This type of siding also has a number of interesting imitations in stock and is perfect for cold regions of our country.

Installation of metal siding under a log

The ability to quickly install metal siding with your own hands ensures its popularity. Moreover, you can do all the installation work yourself, even having the initial construction skills and having the required minimum tool.

The ability to quickly install metal siding with your own hands ensures its popularity. Moreover, you can do all the installation work yourself, even having the initial construction skills and having the required minimum tool.

The work is carried out in the following way:

- The frame is made. Although you can find recommendations on the use of wooden beams for the manufacture of crates, practice shows the feasibility of using a metal profile. The base is made in the same way as for drywall constructions

- Fittings are installed. Corners, starting strips and other structural materials are made of metal of identical color

- Mineral insulation is laid

- Stripes are sewn. Installation starts from the bottom row. For fastening in the strip there are specially designed holes

Self-assembly of metal siding is best done using small strips. To work with a profile longer than 2 meters, you will need at least two workers.

How to choose a metal siding for a log?

In the photographs that are given in this article, only the most popular and common colors of metal siding under a log are indicated. In fact, this material is represented by such a large number of products in all possible shades that often the buyer is faced with a serious problem of choice.

When purchasing using an online store or one of the virtual building supermarkets, it is worth remembering that the color and tonality may differ slightly from the actual shade.

Important! Some varieties of siding for lining a house under a log have a rough texture, this allows for a complete imitation of timber. The facade of such a house after decoration is completely identical to natural. The imitation is so complete that even at close range you may not notice the difference.

Customer reviews

Sergei. I like to do everything with my own hands. When buying a siding under a tree, I had little doubt that it would turn out to install it myself. But everything turned out to be much easier than I expected. Now my old house has changed beyond recognition.

Sergei. I like to do everything with my own hands. When buying a siding under a tree, I had little doubt that it would turn out to install it myself. But everything turned out to be much easier than I expected. Now my old house has changed beyond recognition.

Gennady. I am the owner of the company. On the territory of the enterprise there are several houses for staff. They would like to ennoble with such material, which would not have to be repainted every year. The choice was stopped on a metal siding under a log. The result exceeded expectations. It has already been several winters, but it still looks like new: solid and without visible flaws.

Advantages and disadvantages of the material

The main advantages of metal siding include:

- Decorativeness. The coating has a rich color, texture and texture that mimics a rounded log.

- Fire safety. Material does not burn and does not spread flame.

- Durability and immunity to moisture. The stability of the products is quite high: even with significant mechanical impact, the integrity is not violated. The panels are also able to withstand significant temperature fluctuations and prolonged precipitation.

- Easy installation. All work can be done with your own hands without the involvement of specialists.

- Durability. With proper installation, the service life is more than 30 years. The decorative layer perfectly withstands UV exposure.

- Environmental friendliness. The product, even with strong heating, does not emit substances harmful to health.

- Availability. The cost of the material is quite affordable. Panels can also be customized.

Excellent performance and affordable price explain the reason for the popularity of metal siding

Excellent performance and affordable price explain the reason for the popularity of metal sidingThe main disadvantages of the product:

- Weight. The coating puts a strain on the base and foundation, so it may be necessary to strengthen them.

- Lack of thermal insulation properties. To reduce losses, warming is carried out.

- The impossibility of restoration. Damaged panels will not be able to return the exact geometric shape.

Many owners of houses and cottages with iron coating note that in hot weather the surface heats up very much, this sometimes contributes to an increase in temperature in the rooms. But such a problem is observed when using a dark shade, installed without a ventilation gap.

Profiles and dimensions of the metal block house

This type of cladding is available in two forms: a single-row profile and combined panels (with two rows).

The first variety is a better solution, it better reproduces the imitation of natural wood, since the joints between the strips look uniform. In addition, this option minimizes waste and eliminates the need to change a large fragment with significant damage.

The size of the block house panels depends on the manufacturer, but the most common parameters are as follows:

- the width of a single-fracture product is 18–21 cm, of a double-fracture product - from 23 to 35 cm,

- wave depth - 17–37 mm,

- profile length - from 50 cm to 4 m, maximum - 6 m.

It is important to choose the right sizes of metal siding

It is important to choose the right sizes of metal sidingThe panels are made of galvanized steel sheet, subjected to rolling and stamping. Their thickness is from 0.4 to 0.8 mm. Top and bottom parts are covered with protective and decorative compositions and materials.

Installation instructions for metal siding under a log

The technology for fastening such products is not difficult, some difficulties may arise when installing additional elements. All work is divided into stages.

On a note! When manufacturing custom products according to the scheme, it is necessary to carefully conduct all measurements. The fact is that cutting is carried out as accurately as possible, so it will be very problematic to fix errors.

Foundation preparation

In order to finish a country house or cottage with high quality, preliminary preparation of the base is carried out, this will avoid problems in the future. List of works:

- The overall condition of the walls and foundation is assessed. If there are serious flaws or there is no certainty that the structure will cope with the future load, reinforcement is carried out. To do this, the surface is reinforced with a mesh, and additional supports are poured for the foundation.

- In the absence of the need for large-scale processes, the base is cleaned of all unnecessary. If required, the old decorative layer is removed.

- Cracks and crevices are stitched and covered.

- The surface is treated with antiseptics. If the facade is made of combustible materials, then flame retardants are additionally used.

- Interfering sections of communications are removed or ways to bypass them are thought out.

It is advisable to foresee the replacement of window and doorways, provided that they are sheathed together with the installation of the siding.

The construction of the lathing and insulation

Due to the fact that the metal siding block house requires an even plane for installation, a crate is pre-erected.

The design of the lathing depends on whether or not to use insulation when covering the house

The design of the lathing depends on whether or not to use insulation when covering the house

- A wooden beam is treated with antiseptics and flame retardants and fixed directly to the wall, a spacer is laid for alignment. Racks are set in level with a step of 50-60 cm and are fixed with screws and dowels.

On a note! When creating a ventilated facade, a counter-lattice is pre-laid on which the insulation is fixed, and the main racks are stretched from above.

Regardless of the choice of material for the lathing, the facing of window and door openings is separately performed. They are framed around the entire perimeter from the outside by uprights connected to a common frame.

It is also necessary to provide for the laying of insulation in the cells (if a wooden beam was used).

To maintain heat, you can use any kind of insulation

To maintain heat, you can use any kind of insulation

When creating a crate from a metal profile, it is taken into account that thermal insulation should not impede steam exchange. Insulation in the form of plates is impaled on the installed brackets (suspensions) for the racks of the frame. For additional fixation, special plastic dowels with a large hat are used. The material is spaced apart to exclude the coincidence of the joints of the rows, corner joints are overlapped. All slots are processed with mounting foam, a waterproof vapor-permeable membrane is laid on top.

Component Installation

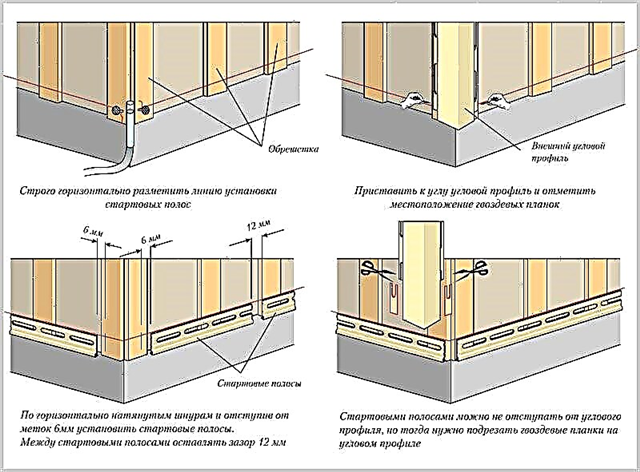

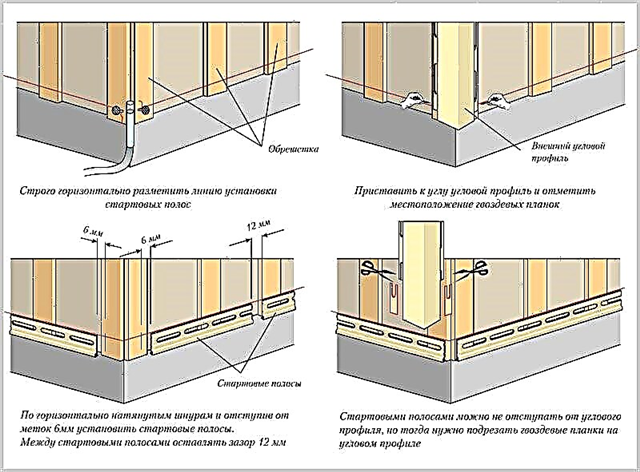

The facade is assembled step by step and includes the following actions:

- Installation of the starting bar. The profile leans against the corners, its boundaries are marked. If you plan to start it at an angle, then the inside of the corner segment is cut. Then, the reference point for the panels is determined from below, it should be at a distance of 4-5 mm from the ground.

If a separate basement device is intended, then the measurement is carried out from it taking into account the previously mounted tide. From the conditional line you need to retreat 4 cm up and make marks on which the bar is set.

Self-tapping screws are located in the center of the holes. It is recommended that they are not screwed in tightly to avoid the effects of possible thermal expansion. If one initial strip is not enough, a gap of 6-10 mm is set between adjacent parts. - Installation of corner elements. On the starting strip, external and internal angles are set. They must be mounted 10 mm lower. Segments are measured and cut, fixing takes place on self-tapping screws. The process is level controlled.

There are two types of corner profiles: for outer and inner corners. Measured in linear meters and have a length of 3 m

There are two types of corner profiles: for outer and inner corners. Measured in linear meters and have a length of 3 m

Attention! If the siding is made to order, then in the absence of relevant experience, it is recommended to initially install all the elements and only after that take accurate measurements.

Panel Mounting

Paneling is as follows:

- The first part is inserted into the corner profile on both sides (or into the connecting strip). It is lowered to combine with the starting rail.

- The screws are screwed into the holes on top with a small gap so that the metal does not deform in hot weather.

- The next element is superimposed on the previous one and rises to connect the locks.

- Each 3-4th part is checked by level.

- The last element is stacked in two ways. The first (more aesthetic) involves the use of a special tool - a punch. They break through the hooks that will be fixed on the finish bar, fixed under the cornice. Such work is performed after trimming and bending of the fragment.

A simpler option is the installation of the last panel in one piece. The transition will be hidden by spotlights and patch angle.

In the absence of experience in mounting angular and connecting elements, the sheathing parts are located only along the starting profile, angles and joints are hidden by simple overlays.

Work with window and doorways

Several methods can be used for this process:

- The easiest way. Installation of siding on the frame to the edge of the opening. In this case, no additional elements apply. Finishing occurs later: slopes are installed for windows and doors, separately framed by platbands. Work is carried out before the installation of the main panels.

- An alternative way. The opening is measured, the platband having connecting holes for slats is cut on the outside. Parts are cut at an angle of 45 degrees to ensure a complete composition. At window openings the ebb is previously exposed.

- The third method. At the outer corners, a corner element is fixed to fix the panels. It is cut to the desired size, then J-strips and a universal profile are mounted on the inside of the opening. The slope is filled with chopped spotlights, and if the distance allows it, with panels cut to the desired size. The inserts are located between the corner elements and the inner bar.

Due to the fact that the sale does not always meet all the necessary additional elements, it is necessary to proceed from the available opportunities and the specific situation.

Metal siding "under the log" - installation instructions step by step

One of the most popular materials for modern finishes is metal siding in the form of logs.

This wall decoration is made of galvanized steel, and looks like wood. But since such an interesting imitation has good characteristics of strength and reliability, iron siding under a log is one of the best ways to decorate the exterior walls of a house.

Preparing walls before installing siding

Anyone who wants to install metal siding on their own will benefit from this instruction for installing metal siding under a log.

Before starting the installation of steel panels and their additional elements, a number of preparatory work will be required:

- For high-quality installation, which in the future will pay off for long-term, you will need to bring the walls of the house in perfect order: the surface should be smooth and clean.

- To do this, remove the remains of the old plaster, climbing plants and fastenings of the drainage system.

- These unnecessary elements can become a significant obstacle during installation.

- Another point of preparation will be the collection of necessary tools for wall cladding and other works.

Preparatory work before installation

Preparatory work before installation

These tools are:

In the event that during the preparatory work, deep recesses, cracks or bulges in the wall were found, then definitely the crate of the walls will be required:

- The lath serves as a frame on which, after laying the insulation and carrying out waterproofing works, a metal siding is installed.

Also, this process is necessary for better ventilation at home. The crate is made of metal or wood.

Lathing and insulation of the exterior walls of the house

Almost always, the installation of metal siding under a log is accompanied by a pre-installed frame under the siding - crate of walls.

- To install siding.

- Thermal insulation of the house outside and ventilation.

Important! The metal profile should have stiffening ribs, lateral bends and indented points.

- These profile functions will significantly increase the mechanical strength of the structure.

When buying crate elements, it is better to independently measure the parameters: thickness, for example, using a caliper.

So, the surface is prepared: the walls are cleaned, the gutters are dismantled.

The next stage of the crate:

- Marking walls and determining the appropriate step.

- The second depends on the density and severity of the cladding panels. The average step of the crate is 40-60 mm.

Tip. In places with strong winds, the step of the crate is better to reduce.

- The frame is mounted vertically or horizontally.

Depending on how the profiles are installed, they install siding. If the frame is mounted vertically, then the panels are horizontal and vice versa.

The most commonly used U-shaped profiles with a cross section of 27x60 mm and a length of 3 m.

Further actions take place according to such a plan:

- Start mounting profiles at the edges of the walls. They can then be oriented to level the surface.

- Drilling holes with a perforator according to the intended marking, the dowels are inserted here and the brackets for the profiles are fixed.

- Installation of insulation boards by putting them on brackets that were previously fixed in the walls. Also at this stage, waterproofing and ventilation works are carried out.

- Installation of lathing profiles. To align all profiles, pull the cord between the installed strips.

The connection of the basic elements of the frame with jumpers made from the remains of the profile.

Installation Tips

Metal siding “under the log” is a universal long-term method of finishing external walls.

Its main advantages are:

- Strength due to the multilayer steel panel structure system,

- Fire safety

- Stability under climatic conditions,

- Resistance to sunlight

- Environmental friendliness

- Ease of care for the facade,

- Aesthetics and universal design,

Another and quite attractive plus of the metal finish is an acceptable cost in comparison with other types of siding.

How to install metal siding under a log with your own hands

Metal siding is an excellent finishing material. It can be used to clad a newly built building or to decorate an old house.

Metal siding is an excellent finishing material. It can be used to clad a newly built building or to decorate an old house.

By itself, it imitates the planking. Metal siding is made of galvanized steel, polymer coated steel or aluminum.

Advantages and disadvantages of the material

- This type of copes with external factors, which makes it very reliable. Precipitation will not be able to reduce its characteristics, the sun will not affect the color and coloring.

- It counteracts both moderately acidic and alkaline environments.

- The above two factors lead to another plus - it does not lend itself to corrosion.

- It is inexpensive, both when buying and in circulation. Its repair and maintenance will not take much time, and it will cost a penny.

- It is fixed so that the joints can hardly be seen. It improves the look of your home, making it more attractive.

- No representative of fire departments will be able to cling to this type of siding, since it does not burn. That is why it is often used in the construction of car washes, as well as gas stations.

- It does not change its appearance and properties under the influence of natural phenomena: snow, frost, sun, heat, rain. Its temperature regimes jump from -50 to + 60-70 degrees Celsius.

- He will be able to serve you for about 50 years, or even more, depending on its use and external factors, which makes this type of siding the most durable compared to the rest.

- It is indifferent to a humid environment: it does not absorb moisture, does not rot.

- It is environmentally friendly to use, since plastic, chemicals, resins, which emit harmful substances into the environment, are not used in production.

- It can be installed both vertically and horizontally.

- It imitates a tree completely, especially when choosing such shades of color as “rosewood” or “alder”.

- Between the rails of the frame, heat-insulating material can be laid.

- It passes air well, that is, even boards under the siding will not attach various kinds of “fungi” to themselves.

Among all the many positive aspects of using this type of material, it is worth highlighting the existing disadvantages:

- Due to the use of a large number of elements, the load on the foundation of the building increases. This should be taken seriously and all pre-calculated.

- If the metal siding receives any damage or even a slight scratch, then it will no longer be possible to get rid of it, but you will have to purchase a new panel.

Varieties of metal panels under the log

There are a large number of classifications, but it is worth highlighting the main ones.

- Russian version. It has worse quality in comparison with foreign counterparts, but wins in value.

- Finnish versionmade of steel coated with a special polymer film.

- British versionhaving a peculiar coating of polyester, which in turn increases the service life of the product and its quality.

- American option made only of aluminum. This reduces both overall weight and cost.

Panel color options

Depending on the design and installation features:

- Front siding. From the name itself it is clear that it is used only to decorate the facade of the house. It is more reliable and resistant to sun and moisture.

- Perforated.

- Siding that applies for ceiling decoration, It is recommended to install it only in the warm season. Low temperatures can have a negative effect and damage its elements.

- In cities and villages with constantly low temperatures, siding gained great popularity. together with a heater. It consists of several layers.

- For the decoration of industrial buildings, its simplest form is most often used - smoothwhich does not have any features.

- Imitating wood, that is, the kind of panels we are considering with imitation under a log.

Technical specifications and dimensions

The characteristics associated with the operation of metal siding, in the first place, are closely intertwined with its positive qualities - it is durability, resistance to various kinds of influences, as well as corrosion resistance.

When ordering, you indicate the length and width of the panels you need, and it is precisely this size that you will receive exactly to the millimeter. Siding can be mounted both horizontally and vertically. Installation work can be done at any time of the year, with the exception of the cases when manufacturers themselves recommend this only at positive temperatures. All elements of metal siding are reliable, especially with regard to the castle part.

When ordering, you indicate the length and width of the panels you need, and it is precisely this size that you will receive exactly to the millimeter. Siding can be mounted both horizontally and vertically. Installation work can be done at any time of the year, with the exception of the cases when manufacturers themselves recommend this only at positive temperatures. All elements of metal siding are reliable, especially with regard to the castle part.

As for the dimensions of the elements of the material, much depends on the manufacturer itself, from which they can enter the market from the smallest 0.5 * 0.26 m to a length of 6 meters. Siding is also different in the thickness of each of its parts. You can find panels with a thickness of 4-5 mm, and most often it reaches 20-22 mm. The height of each element may not exceed 14 mm. The average weight of one panel varies around 4-5 kilograms.

Among the features, it is also worth highlighting that the field of application of the material is so high that it is widely used in industry, construction and as an element of decor.

Major manufacturers

If we consider the manufacturers of this material, then first of all they need to be divided into domestic and world.

As for Russia, the following companies can be noted here:

- FineBer. True, this company is mainly engaged in the production of vinyl siding.

- One of the young but experienced companies is Nordsight LLC.

- LLC "Duke Extra".

World-class manufacturers:

- Mitten Vinyl Inc. A company from Canada that has been operating for over 60 years.

- Kaycan Ltd. The most developed area is vinyl panels.

- American companies engaged in the production of siding of all forms and types:

- CertainTeed, which has been pleasing its customers for over 100 years and has around fifty plants throughout North America.

- Nailite is another American company. Its main product is siding for private homes and office premises.

- Gentek.

- Ruukki (Finland), Corus Group (Great Britain) - European leaders.

Installation procedure

If you decide to make the wall cladding of your house using metal siding, then you should adhere to the basic rules and do everything in sequence:

- If possible, we clear the surface of all unnecessary parts: garbage, old plaster, significant irregularities.

- It is necessary to mark the places on the wall where the brackets will be mounted. They can be fixed with screws or nails. Using brackets allows you to level the wall by fixing them in the right place. If the walls are curved, then it is best to fix them at a distance of about 50 cm from each other, but if they are even, 80-90 cm are enough.

- Carefully measure the size we need and cut the panel with a hacksaw. In this case, you need to put it on a flat surface to avoid bending.

- We take a beam 5 * 5 cm in size and make a crate so that the walls "breathe". The frame should be along the entire length of the wall, at the corners of the building, around windows and doorways. It can be screwed onto the wall with screws or nailed. The crate should not be done if we did not see differences in the level above 2 cm per 10 m 2. These minor flaws can eliminate metal siding.

- To keep the heat in the house, we lay a heater from top to bottom. To keep it in place, it is screwed with wire. How to choose a heater - depends on desire and finances.

- When we have completed all of the above items, we proceed with the installation of siding directly. Since the weight of each panel is an average of 5 kilograms, it is best to use an assistant. He lifts the sheet, and you screw it with screws. After installing the first sheet, insert the second into the grooves of the first, check everything using the building level and only then fasten with fasteners.

In this case, you must adhere to some rules:

- Leave a gap of 1-2 mm between the screw head and the sheet itself in case of expansion or contraction over time.

- Panels must be installed from the corner of the building.

Consumer Reviews

- “Having decided to improve the appearance of my house, I used a siding made of metal under a log. And did not regret it. It made my house more fresh, modern. Installation did not make any problems, especially since the panels have holes for self-tapping screws. Wood siding is the best option for decorating a private house, because after installing it everything looks as if the house was just built ”- Anton, Samara.

- “There are plenty of options for exterior decoration at home. But I nevertheless settled on a metal siding. Simple vinyl panels have become so simple that it is better to sheathe sheds, rather than at home. In addition, the wood version looks natural and natural. I personally mounted the siding myself, it took some time, but the result was only pleasing. The installation was carried out almost 10 years ago, but there were no changes in the casing, it feels like I did it only yesterday ”- Oleg, St. Petersburg.

Photo gallery of houses sheathed with this material

The photo below shows the results of works on the decoration of facades with wood panels:

Metal siding for logs - material description and facade cladding tips

Metal siding under a log

There are a number of finishing materials on the market that allow customers to achieve their requests for the arrangement of facades.

Log siding is one of those materials whose sales have grown significantly in recent years. In many ways, this situation is due to the excellent characteristics of the material and the speed of installation of the cladding.

A wooden log house is a dream of many people, which can become a reality, because a house of any material can be trimmed with siding to simulate logs.

Siding with the texture of natural wood is almost indistinguishable from the real natural material. At the same time, metal siding has performance characteristics much better than that of wood.

Features of log siding

Metal siding for wood imitation

Metal siding is designed to create a ventilated facade, so its installation has a number of features.

Usually, under the material, the installation of the lathing, insulation and waterproofing is carried out. However, the installation of insulation may not be carried out if the house is located in a region with constantly positive temperatures.

The crate is also not always required - it will be described in more detail below.

Among the features of the material include the composition of its structure. So, metal siding under a bar is a structure of the following elements:

- Metal siding panels,

- Start and finish strips,

- External and internal corner strips,

- Elements for decoration around door and window openings.

Such a composition of the cladding kit allows you to create a finished composition, moreover, very highly protected from external influences. Some accessories are allowed not to be used, instead of trimming the main panels, but in this case, it is possible to reduce the technological properties of the cladding.

Scope of metal siding under a log

This type of siding is perfect for simulating a wooden surface.

The cost of metal siding for a log is significantly lower than the cost of natural wood, so this type of siding is applicable almost everywhere where you want to simulate a natural tree.

The material can be used for interior decoration, especially in cases where increased fire safety is required. Sometimes, it is possible to use for the construction of fences and other fences.

Finishing a house under a log using metal siding is possible both with the involvement of third-party specialists, and with your own hands. In the latter case, the ease of installation is ensured by the low weight of the material and simple mounting technology, reminiscent of the collection of the designer.

After installation, the cladding does not require complicated maintenance. The material is resistant to all types of external influences. Even if dirt has got on the surface of the siding, it can easily be cleaned with pressure from a watering hose.

Preparing the facade for installation

The metal siding panel may have the following dimensions

Installation of facade panels under imitation of a log requires certain preparatory measures. All manipulations will be simplified as much as possible if the facade surface was initially smooth.

The verticality of the walls is determined using the building level - if a difference of more than 2 cm by 10 linear meters is not detected, then the crate can not be done.

All the defects of the facade will be hidden, so that careful refining of the surface can be omitted. However, measures such as the removal of rendered plaster and old cladding are mandatory. All structures, such as gutters and roller shutters, must be temporarily removed.

The following tools will be required to complete the installation of metal siding:

If the inspection of the facade revealed significant deviations of the wall from the vertical and other defects, such as depressions, bulges and cracks, it is necessary to install the battens.

It will allow for the installation of metal siding in compliance with all standards and instructions, will allow you to evenly install panels and provide good ventilation of the facade. The lathing is made of wood or metal.

Bars for wooden crates should have a moisture content of less than 14%. As a rule, most of the timber timber sold has a moisture content that exceeds this indicator. A lath made of wet wood will sooner or later begin to dry and warp, as a result of which the entire lining will go in waves.

Metal profiles are mounted with a step from 40 to 100 cm. The optimal step is selected based on the building structure, the width of the insulation, as well as future operating conditions.

The metal profile is mounted in increments of 40 to 100 centimeters

Consideration of the building structure implies that near the windows, doors and structures that are supposed to be installed on the facade, the lathing pitch should be reduced. Also, the step should correspond to the width of the insulation.

Finally, the location of the building in a windy region implies a decrease in the step of the crate, so that the siding sits more tightly.

Such a wide gap for choosing the step is the advantage of metal panels under the tree. For comparison, the crate for vinyl panels can be installed in increments of not more than 60 cm. The installation of additional crate elements is required along the perimeter of windows and doors.

Next, metal siding should be insulated - installation involves laying insulation plates between the elements of the crate. When choosing a heat-insulating material, attention should be paid to the moisture absorption coefficient - it should be as small as possible.

General scheme of the facades of metal siding

In order for the insulation not to slip, it is fixed on top with an additional rail. In addition, each individual piece of material must be secured using plate-shaped dowels.

Now it’s time to install the accessories that come with the siding. Additional elements are mounted under the eaves, in the lower part of the walls, at the corners of the house, as well as around the perimeter of the openings.

Elements such as finishing strips are installed after the installation of the main panels, when you come to the top of the walls of the building.

All accessories are attached to the crate using self-tapping screws. The fastening step is 20-40 cm. The choice of a specific fastening step is made according to the same principle as the crate step was chosen.

After completing the preparatory work, you should examine everything for any shortcomings - it is easier to eliminate them at this stage, otherwise you may then need to dismantle individual siding paintings.

Assembly instructions for main panels

During installation, various additional elements are used - docking strips, external and internal corners

The most difficult stages of work are behind - now it remains only to assemble the previously mentioned constructor:

- The installation of panels should begin from the corners of the building.

- Fastening is carried out using self-tapping screws and hooks of each upper panel to the lower one with the help of lock joints specially provided for this.

- When attaching metal siding, the dimensions of the panels may not allow covering the entire building with standard products. In this case, the panels must be sawn with a hacksaw. Do not use a grinder, as a hot disc can damage the protective siding layer.

When adjusting the required sizes, it is better to use a hacksaw for metal

If somewhere a slight deviation from the horizontal appears, with the installation of each subsequent panel, this deviation will gradually increase - therefore, it is recommended, after installing each pair of facing paintings, to check their orientation according to damage.

In many ways, the technology of installing metal siding under a log is not much different from installing other types of siding panels.

Metal siding for logs - installation features

Do you live in a house that has long been in need of painting, and warming would not hurt him? Then you are offered a combined solution - two in one. And note, you can forget about staining for a very long time.

Our instruction will not only show the possibilities of finishing material - siding, but also describe the technology of its installation. Let's get started.

Photos of the final result.

Why siding

Siding? Why not!

Siding is material that has been developed taking into account the flaws and flaws of the outer lining. Talk about the priority of choice:

Finishing with metal siding under a log allows not only to put the walls in a new strong and sufficiently durable coating, but also to completely change its exterior.

At the exit, you get a house, as if just collected from a log.

- The material withstands temperature extremes in the range up to 120 degrees Celsius: from minus to plus 60 degrees. This allows the installation of metal siding under a log in almost any region,

- It was not in vain that we compared this material with lining, the service life of the coating is three times that of lining,

- Very easy care, comparable to children's fun watering with a hose. Dust and dirt are washed away, and your home shines with cleanliness,

- Siding is very easy to do with your own hands.

Note! The simplicity of the set is not surprising, minor difficulties may arise when fixing the starting bar, but to solve this problem, our instruction for installing metal siding under a log has been developed.

Calculation is needed everywhere.

Any repair or construction work is preceded by calculation.

In this context, the calculation will be made on the main material, and on various trims, window and door profiles:

- Let's start with a general count. First of all, we will be interested in the entire area to be closed. Recall geometric tricks: the wall area of a house is a product of two quantities, quite rightly - length and height. Summarize the area of all walls,

For your information! If your house does not have triangular gables, then this calculation of the total area can be completed, not forgetting to take away from the total amount of the area of windows, doors. Otherwise, we recall the area of the triangle, and it will be equal to half the product of height by width.

- Metal siding for a log is calculated according to this scheme: we divide the area of one sheet by the total obtained area of the building and add here another 7% for waste from cutting material in corners and in window (door) openings,

Technical features! Before buying material, be sure to ask the seller what is the area of available material. Maybe 0.85 square meters, maybe 1.37 squares.

Having learned the product parameter, calculate the required quantity with a small add-on, and then buy.

- The start profile, the conversation is special, because the main difficulty in the set is the exposure of this particular element. It is calculated as follows - the length of the perimeter of the entire building is divided by the length of one bar, we get the number,

- Corner structures - they can be internal or external. Your task is to calculate the number and type of corners in your building, and divide the total length by the size of the metal siding under the log. At the output we have the quantity

- Plank connecting. This component of the designer allows you to close the joints of the joints and the calculation for these elements is carried out on the previous path,

- Finishing and window profiles. These items are optional and can be replaced. They are recruited individually. The finishing bar goes to the end of the installation, the windows on the openings of windows, doors.

Why two in one

For normal fixing of siding to the wall, a crate is needed, it can also be used as a limiter for insulation.

Here about it and in more detail:

- The first structural element, of course, is the crate. It is presented either with metal profiles, as for attaching drywall, or with a wooden beam

section of 50x80 mm, 50x50 mm. Installation of profiles occurs in increments of 40 centimeters, fixing to the wall - with the help of U-shaped mounts with self-tapping screws.

Metal profiles installed.

Advice! If your walls have led from time to time, but these changes are insignificant, then wooden beams can be used for lathing. If the unevenness of the wall topography is visible visually, then you can’t do without a metal profile, because these beams must be adjusted to a single level.

- The second element is insulation. Mineral wool has proven itself very well, but good reviews also about modern foam plastic materials. The material used for insulation is fixed to the wall using umbrellas - special fasteners.

We will replace metal with wood.

Note! Unlike polystyrene, cotton wool does not like moisture and can shrink into lumps. It is clear that there is no need to talk about any thermal protection after this. To avoid this, cotton wool is additionally covered with a diffusion membrane.

Installation of metal siding under the log with your own hands begins with the installation of a drainage system. According to the color scheme, it can copy metal siding and a log, it can be contrasting or emphasizing, this is a matter of taste.

The rest of the process looks like this:

- On the perimeter, the ebb and the starting bar are installed. The complexity of this stage is to expose all this in a single level. There are tools for this - normal and water levels,

- And then the conveyor turns on. Laying of wall strips is combined with laying of connectors, external and internal corners. And so to the very top. Window profiles can be replaced with siding trim and even save on it.

Photo - during installation

Advice! After installing the finish strip, which is also often replaced with the usual bar, spotlights are installed according to the technology. These are special constructions with openings for normal air circulation and preventing stagnation. They are often replaced, but we would recommend not to do this - air movement between the siding and the wall should be required.

Metal siding: varieties, properties, advantages of panels “under the log”

One of the most durable and aesthetic solutions for decorating facades today is metal siding under a log, which, due to the properties of the material, is distinguished by practicality and durability. Easy to care for and installation of cladding for exterior walls is popular, since under various operating conditions, the coating, as a rule, does not lose its properties.

The use of metal panels

It so happened that the finishing with metal material is used in the construction of industrial and public buildings. This is due to the properties of the metal, because wood and vinyl panels can create a more favorable indoor climate and a warm, cozy exterior of the house. Cold material is not customary to use in the arrangement of private houses. Therefore, metal siding is used mainly for decorating the facades of industrial premises. But the development by manufacturers of special metal sheathing imitating a log made it possible to choose a strong and durable finish for the private sector.

Log siding metal siding

Metal siding under a log is often called a block house, although this is the original name for solid cladding. Although outwardly metal panels really look like wood panels. They fully correspond to the types of material described above - with a primer and a polymer coating. The finish layer is fully consistent with the texture of natural wood.

In this case, the color scheme and, of course, the variety of “tree” can be any, since the possibilities of the technology for transmitting a natural pattern are unlimited.

Performance characteristics of metal siding

Metal siding has characteristic properties that are determined by the technical parameters of the material:

- The metal does not burn. This is the defining property of panels for the decoration of buildings in which the risk of fire is increased. The polymer coating and paint may become deformed and peel off during exposure to fire. At the same time, internal structures will not be affected if the flame sneaks outside.

- Accordingly, the material is resistant to sharp temperature fluctuations - within the operating range from -50 ° C to + 80 ° C. This range allows you to clad facades of buildings in a wide climatic zone and operate the coating in various weather conditions.

- The expansion of the metal during heating is not as significant as vinyl siding, so there is no need to calculate the clearance during installation and worry about the deformation of the panels after installation.

- Corrosion resistance is provided by a primer and a polymer coating. But it should be remembered that during installation, some elements are shortened and cut. In these places, a violation of the protective coating occurs and then corrosion begins. You should also remember about the inadmissibility of combining metal products and aluminum alloys, a vivid example is an aluminum rivet and a steel siding sheet. The photo shows what will happen when these metals are combined.

- The finish coating of the metal also protects the siding from high humidity, direct sunlight, and also makes the lining resistant to various chemical compounds - acids, alkalis.

- Wood siding is environmentally friendly and safe for the environment and human health.

- Durability is also due to the properties of the metal, which is durable and resistant to various kinds. Aluminum options are more susceptible to mechanical damage - they are easy to bend with a blow, so transportation should be accurate.

- The weight of metal siding can be different: steel weighs much more than vinyl and aluminum panels.

With proper care, this type of finish retains its appearance for a long time. It is important to eliminate scratches in a timely manner, to monitor the integrity of the polymer coating, which lays the main protective function.

Storage and delivery of metal siding

Storage conditions for maintaining the quality and properties of metal siding, as a rule, are not as important as for wood. Of course, it is optimal to provide a normal level of humidity in the room (it is important that it is not increased) at low air temperature. In more aggressive conditions, the panels will not lose their properties, but their service life may be reduced.

More important are the transportation conditions:

- The panels must be well-packed to prevent mechanical damage,

- Packaging with metal siding should be carefully fixed in the car body,

- Do not place or load any other objects on top of the material.

To a certain extent, metal sheets are subject to mechanical deformation in the event of a strong impact, therefore it is important to deliver them intact. Any damage to the polymer layer - scratches and chips - leads to premature development of corrosion, so this danger should be avoided.

Since the block house has a semicircular shape, the risk of damage to such a material is higher than flat panels. Therefore, they are transported in packages in several layers to maintain the strength and integrity of the material.

Installation of metal siding

Metal panels are supplied with a lock system as standard, which greatly facilitates the installation process, and also ensures the reliability and integrity of the finished coating.

So that the installation does not bring surprises, it is important to purchase 10% more material than the calculated one. This difference is necessary to compensate for panel trim in individual architectural elements.

As a rule, metal siding is installed on clean walls, which it is advisable to insulate before, of course, if we are talking about a heated building. Further installation is carried out in the usual way:

- Facades are repaired if they have cracks and deformations.

- A frame is mounted on the walls - guide profiles. Since it is planned to mount metal siding, the base must also be assembled from steel or aluminum parts. The use of other materials may be impractical and even impossible if you choose a wooden crate and install in wet weather.

- If necessary, insulating material is mounted on the walls. If it is used, it is necessary to organize ventilation and the exit of moisture outside from under the skin of the building.

- The guides for the lathing are set in steps of 40-60 cm. The lathing installed at the level will preserve the geometry of the structure for a long time.

- Around the windows and doorways install additional profiles.

- Start laying metal siding from the bottom of the facades. Starting panels are mounted around the entire perimeter of the building, observing a horizontal line using the level and, accordingly, the starting profile.

- For fastening use screws. They must be fastened no less than 40 cm.

- Each subsequent panel is installed so that it fits into the “lock” with the previous one. Hats of hardware hide under the junction.

- The corners and joints between the panels of the same row are covered with connecting elements that make the seams not only neat, but also more airtight. Similar linings are used to decorate facades around the perimeter of window and door openings.

Thus, metal imitating wood is the optimal solution for a durable finish, which even an amateur will cope with the installation.

Scope of use

Metal siding materials are especially often used in the construction of public and industrial buildings. Consumers have always rarely chosen metal coatings for private houses, because they do not provide a favorable climate in the premises and are not associated with comfort, domestic warmth (unlike, for example, natural wood). But production technologies are now being actively improved, and modern companies offer metal materials that are quite suitable for finishing private residential buildings.

Transportation and storage

In order for all the properties and characteristics of metal siding panels to remain the same, it is necessary to create optimal storage conditions for such materials. It is worth noting that this recommendation is not as important as in cases with wooden products: in this regard, with metal siding is much more convenient.

Make sure that the air temperature is relatively low in the room where the coatings will be stored. Pay attention to humidity: it should not be too high. If the conditions at the storage location are unfavorable, the service life of the products may be reduced.

The delivery conditions for metal siding panels are more important:

- Do not put anything else on the panel. Although they are characterized by increased strength, but under the influence of considerable weight they may well be damaged.

- When planning to transport siding in the back of a car, carefully secure the material.

- To avoid mechanical damage, coatings should be packaged in good quality.

Remember that panels can become deformed when exposed to strong impacts. They should be protected during transportation. If the additional protective layer on the material is damaged, it is very likely that in the future you will have to face such a problem as corrosion.

Since the block house - as siding panels under the log is also called - is semicircular, the risk of damage increases significantly. On such surfaces, defects occur more often. So that during transportation such materials remain integral and durable, it is better to put them in several layers (they should not move freely in the package during the trip).

Installation work

Installation of metal siding panels is a work that is not very difficult, but various important nuances must be taken into account when implementing it. Finishing is carried out in several stages.

Remember that you will need to first take care of all measurements. It is necessary to carry out cutting with maximum accuracy. Otherwise, you will spend a lot of time fixing errors, and it will be very difficult to deal with them.

How to prepare the surface?

If you want the finish to be as high-quality as possible, you will first need to carefully prepare the surface. This way you can avoid serious problems in the future. Some recommendations need to be considered:

- Examine the foundation, walls and evaluate the condition they are in. In the event that you are not sure that the foundation will cope with a significant load (or there are serious defects), you will have to strengthen it. To do this, fill in additional support for the foundation and reinforce the base with mesh.

- If necessary, clean off the old paintwork and its peeling pieces. Remove any excess from the surface.

- Cracks and cracks will need to be covered.

- Apply an antiseptic coating to the base. If combustible materials were used to create the wall, also use flame retardants.

- Think about how you can get around the communication areas that interfere with the finishing work. If possible, delete them.

Warming and crate

Since metal siding panels need to be installed on the most even base, you will have to take care of creating a crate. It must be built using the recommendations of specialists.

- Apply flame retardants and antiseptics to the wooden beam, attach it to the base. Lay the backing to make the structure even. Using a level, set up the posts in increments of 0.5-0.6 m. Fix them with dowels and self-tapping screws. If the facade is ventilated, you will need to first install the counter grill. Fix the insulation on it and extend the main posts from above.

- It is possible to make a crate on suspensions. For this, U-shaped galvanized profiles are used. On the basis, you will need to outline the lines: on them you will fix the brackets, using screws and dowels for this. Cut racks of the necessary sizes and fix them on suspensions, using level. Jumpers are used for added rigidity.

Regardless of how you carry out the crate, you will also need to additionally veneer the door and window openings. From the outside, around the entire perimeter, frame them with racks. These elements should be connected to a common frame. If a timber beam was used, it is necessary to lay the insulation in the cells.

If the crate was created from a metal profile, it should be noted that the heat-insulating material should not interfere with the implementation of steam exchange. The plates providing thermal insulation must be fixed on the suspensions (brackets) for the racks of the frame. With the help of special dowels made of plastic, additional fixation should be provided.

Accessories

Accessories are installed in a specific order.

- Set the starting bar. Attach the profile to the corners, then you will need to mark its borders. For panels, a reference point (bottom) should be defined. From the ground it is placed at a distance of 0.4-0.5 cm.

- Focusing on the starting strip, install the corner elements. Corners need to be set 1 cm lower. These elements should be fixed with screws. To control the process, use a level.

- Install the H-profile, connecting strips. If you plan to finish a wide wall or combine shades, install the connecting strips between the corners. Use the level to align these elements. They need to be fixed using self-tapping screws.

In the case when the siding panels are created to order, and you have little experience in the implementation of such finishing work, you must install all the necessary elements before making accurate measurements. So you can avoid inconsistencies.

Panels

You will need to start installing siding from the corners of the building. To fasten the panels, use self-tapping screws. Special lock connections are also provided: with their help, all the upper elements are attached to the lower ones.

Standard panels sometimes have to be cut, because their dimensions do not always allow covering the entire surface. To do this, you can use a hacksaw for metal products. A hot grinder disc may spoil the protective coating.

Install all the elements until you reach the top. Then install the finishing strips. From above, they will need to be attached using self-tapping screws, because they have locking joints only from the bottom.

Make sure that there are no deviations. With each new element, it will only increase. Do not forget to use the building level: it should be applied after installing each pair of elements.

Such coatings must be carefully looked after: in this case, they will retain aesthetics for a long time. Walls lined with metal siding panels will need to be cleaned from time to time. To do this, you can use a window cleaner and a brush with a not very stiff bristle. Periodically inspect the facade: it should not be chipped or scratched. Having noticed the defects, eliminate them with a primer: the protective polymer coating must be integral.

For other features of metal siding under a log, see the next video.

Main advantages over other types of siding

The benefits of metal siding under a log:

- Simple and quick installation.

- The profile is stamped from galvanized steel, which is well resistant to corrosion.

- There is a protective polymer coating that enhances the resistance of the material to destructive processes.

- High resistance to temperature fluctuations, during severe frosts, the properties of the metal practically do not change, unlike PVC panels.

- Guaranteed service life is higher than that of PVC panels.

- When subjected to mechanical stress, the metal ruptures or bends, while PVC simply breaks.

- Non-combustible material.

From a technical point of view, metal siding under a log has all the qualities inherent in other types of similar metal coatings. All the differences between them are, for the most part, in an aesthetic plane, and there are great advantages.

The surface, having the texture of a log house, looks very traditional, assembled, the whole house is perceived as a whole.

Metal siding is divided into the following types:

House with metal siding under a log

Equipment

Metal siding for a log is available complete with all additional and auxiliary elements for installation and design of joints, transitions, openings and junctions.

Available for sale:

- Inside and outside corners.

- H-profile for longitudinal docking.

- Start and finish profiles.

- Near-window trims.

- Platbands.

- Spotlights.

- Moldings (under the roof).

- J-platbands.

All additional elements have a color, a protective coating identical to that of the main panels, it looks as if they are made of the same kind of wood.

Preparation of the crate and wall insulation

Before installing siding directly it is necessary to carry out preparatory operations - to insulate the outer wall and install the crate, which simultaneously serves to support the insulation and (mainly) is a support for siding.

Before installing siding directly it is necessary to carry out preparatory operations - to insulate the outer wall and install the crate, which simultaneously serves to support the insulation and (mainly) is a support for siding.

As a heater, any material intended for this purpose is used, the main thing is that the basic rule is respected - vapor permeability of materials should follow the outside in increasing order.

This means that the insulation should pass steam better than the wall material.

In addition, to protect against external moisture (atmospheric), to prevent insulation swelling, you will need a layer of a waterproof membrane that releases steam from the inside but does not let it pass from the outside.

The thickness of the battens laths must be not less than the thickness of the insulation. Usually 50 to 50 mm bars are used if slab mineral wool of 50 mm thickness is used.

On top of the main crate, a counter crate is madesupporting siding panels, as well as providing a ventilation gap for condensate discharge. Its thickness is 30-40 mm.

The spacing of the battens is usually about 60 cm, which is convenient for mounting siding panels. Before starting the installation, it is recommended to check the step size for compliance with the available material..

Care must be taken to monitor the presence of the counter-lattice plane. Usually this is done at the stage of installation of the main strips and insulation - if there are flaws or bends in the walls, a layer of leveling plaster is applied.

Nevertheless, it is necessary to control the position of the counter battens using tensioned cords, if necessary, lay pieces of wood, plywood, etc. to level the plane.

The crate can be made of wooden planks, but it is better to use metal guides for drywall.

Setting the start bar

First, the bottom point is chosen, at which the siding should end. From it upwards 40 mm are measured and a horizontal line is drawn (check by level). Along this line, the top edge is combined with it and the starting bar is attached.

Screws are screwed exactly in the center of the holes. They should not be tightened; a small gap should remain to compensate for the temperature movements of the metal. The expansion coefficient of metal siding is 10 times lower than that of vinyl, but tight fastening of elements is not recommended.

Next to the first, the initial bar is installed at a distance of 6 mm from the previous one to compensate for thermal expansionotherwise they can overlap with each other, causing the surface of the cladding to swell.

Setting the start bar

The device is obtuse and sharp corners

Additional elements of metal siding have a flexible structure. If you need to install an obtuse angle, you need to attach the angle profile to the corner and push it until it is completely adjacent to the crate. In this position, it is fixed at the installation site.

To design an acute angle, it is necessary to compress the sides of the angular profile to the desired state and fix it in place. Care should be taken without damaging the protective polymer coating. Typically, such operations with a certain delicacy to the material pass without damage or bruising.

The device is obtuse and sharp corners

Installation of vertical strips - corners and H-shaped connector

Installation of complex angular strips and H-joints is carried out after installation of the starting strip. Their position is controlled by a plumb line.. The step of fastening the screws is 20-30 cm, since the complexity of the profile and the responsible task of the element require reliable fastening, eliminating distortions or other deformations.

Specialists are often advised to set simple angles, especially if the installation is done by untrained people. They are a regular corner without additional profile details.

It is much simpler to fix such elements, since they are superimposed on top of the installed panels and just cover the corner joint. Such installation is carried out using self-tapping screws.twisted into pre-drilled holes, or by blind rivets.

In the second case, the connection looks a little more solid, but it is much more difficult to disassemble it if necessary - you have to drill rivets.

Installation of vertical strips - corners and H-shaped connector

Panel Installation

Usually, the panels are installed horizontally from the bottom up. This arrangement is most natural for wooden buildings.although vertical installation is possible.

The bottom panel is inserted into the corner and H-profiles, latched into the lock of the starting profile, then fixed with screws in the crate. The fastening rules are the same - a small gap is left for the free movement of parts if necessary.

All of the following panels are mounted in this way.. It is recommended to check the horizontal level every 3 panels and adjust the position when deviations are detected.

How to get around siding windows and doorways

The window and door openings are generally the same, but the windows are additionally equipped with low tides to drain rainwater. The procedure is usually dictated by the position of the window or door relative to the plane of the wall.

The window and door openings are generally the same, but the windows are additionally equipped with low tides to drain rainwater. The procedure is usually dictated by the position of the window or door relative to the plane of the wall.

If the design of deep-seated window or door blocks is required, then window-rails are used, in other cases, platbands are used.

First you need to install the crate. The best material for her is a galvanized metal profile. The use of wood is possible, but not recommended by specialists due to possible problems with drying, decay or swelling of the material.

For windows with installation depths less than 20 cm, the J-bar is used.. To install it on the window box around the perimeter, a finishing strip is installed in which the J-strip is installed.

If the installation depth of the window exceeds 20 cm, usually a complex external angle is used, in which the siding strips cut along the length are set. From the side of the window, the siding is limited by a universal bar fixed to the window frame.

If the strips are not long enough, a standard overlap of at least 25 mm is carried out.

For finishing openings that are located in the plane of the wall, platbands are used.. They come in different sizes, the most suitable type is acquired for installation. Installation of platbands is made before installation of panels.

The main problem of such work is the cutting of corner joints at 45 degrees. The accuracy of such a fit ensures a neat appearance of the window and prevents rainwater from entering the slots..

Various miter boxes are usually used, although their accuracy is very relative and does not always correspond to the requirements put forward. Sometimes they make an exact 45 degree angle template, with which they indicate the cut line on the profile.

The best option is the one that gives the most successful result, so there are no unequivocal recommendations in this matter.

How to get around siding windows and doorways

Installation of finishing strips

The finish strip covers the edges of the panels with a perforated edge. Without it, the casing looks unfinished, messy. In addition, the upper roller of the finish strip prevents rainwater from entering the skin.

It is installed almost simultaneously with the last panel, immediately before its installation. The siding strip is cut in width, inserted under the edge of the finish profile, and then fixed in it.

Metal siding under the log - a reliable, durable and effective external coating of the house. The ability to do it yourself, the durability and solidity of the cladding made it popular, preferable, despite the higher cost compared to vinyl or acrylic analogues.

Reliability of the material, a more successful combination of technical characteristics bring metal siding under the log to the category of unconditional leaders among many such materials.

Installation of finishing strips